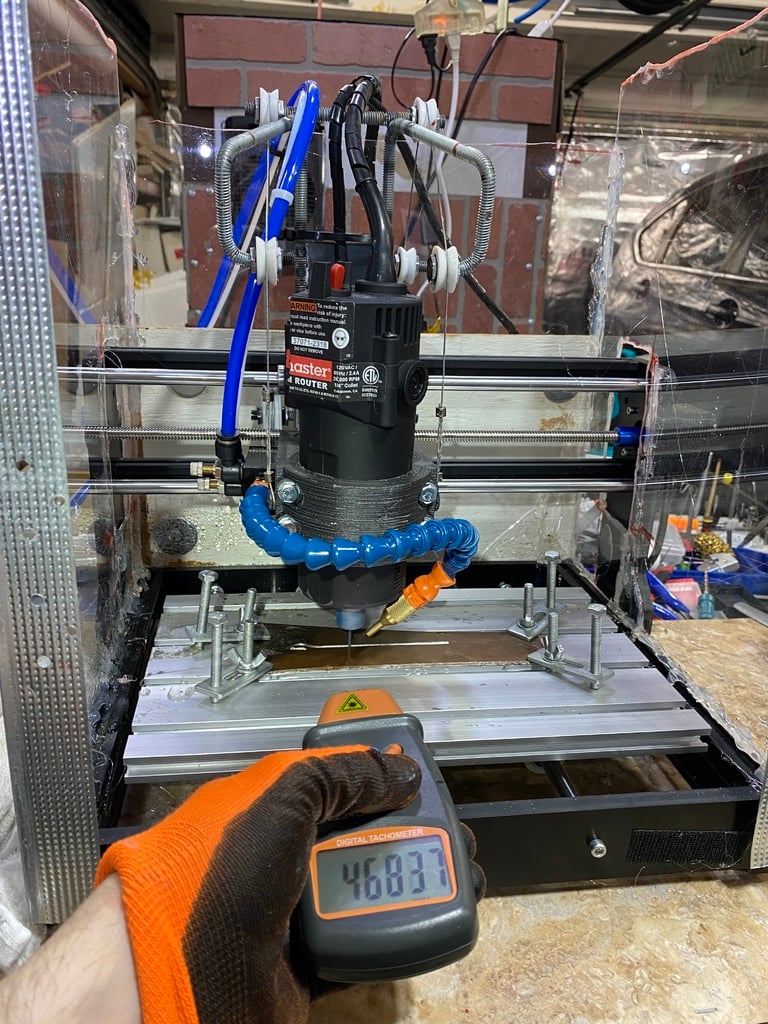

15$ Harbor Freight Router cutting steel and Milling aluminum , 3018 CNC Upgrade 400watt 45,000RPM, 10newton Z axis assist,

thingiverse

Cutting wrench out of old steel lawnmower blade https://youtu.be/R6T-vE0EXu0 milling Al https://youtu.be/mTvyCNx8GyM 10/16/2023: I upgraded to the bauer (makita clone) it was on sale for 50$ But for me this updgrade wasn't needed as I just use for thin metals, This build worked fine for all everything I need. Conclusions on this build, I would argue that this is the cheapest way to upgrade your 3018 in terms of motor and Y and X rigidity. requires a bit of time and metal work, If have the money to burn then linear rails and larger Z stepper: etc. are much easier way to do this. But the upgrades end up costing more than the machine. (120$ open box ) I am really happy with the performance of this build, I had zero dollars for budget on this build, I literally used spare parts are already had in my garage. The router was free (from harbor frieight credit points) you can overvoltage with 220V outlet and speed controller , although this wasn't needed to mill aluminum. This is not ideal for cutting steel, but that was the best way to demonstrate the rigidity and accuracy of the x and z axis upgrade and the efficacy of the z assist. You can skip the speed controller and keep it at 120V and 27,000 and mill soft metals at slow feed rates with 1 or 2 flute. Although the cheap 3-5$ speed controllers should work fine for 2.4amp motor. I do like that this motor is lighter and runs cooler than the Makita router. Noticed a little play Y and X axis on stock 3018 set up its from the play in the t8 screw and nut, I added a 2nd spring to the backlash nut. problem solved. won't budge a milimeter now. a cooling / mist system / fogger is a must, machine mills better preserves expensive bits, keeps them sharper longer. These CNC misting / cooling attachment system are 17$ on Amazon and plug into compressor, First Test Milling of Aluminum: Video link and picture above 33,000rpm , 4 flute 1/8" speed tiger end mill, 140mm/min , .2 depth per pass, could have increased the depth and speed , but this was my first test of aluminum with the completed build. Original collet and nut produce severe bit wobble, you need a Ryobi compatible collet nut (M14 -1) and collets, zip router collets work but the collet nut does not fit Don't mount with out the router without the Two 500gm coil springs and pulley assembly, creates a lever and will start to torque the z and x axis and create bend and play in the frame over time. . Using the springs avoids expensive linear rails and upgrading z stepper, It dampens the z movements increases Z precision, constructed with V groove pulley wheels with dual 688ZZ bearings to reduce z axis load from 1450gm to less than 450gm, also positions load over 20-20 extrusions, added 8 wheels to snap into the 20 - 20 extrusions with a steel bar as acting as spine. Included Images of estimated dimensions on the (8mm or 5/16") threaded rod lengths and angles. used 1.5mm thick piece of sheet steel to reinforce z/x carriage, used 45mm bearing in mount, also added spacer in between x axis bearings to distribute the load. (double check x rod column diameter before you print file, not sure what size I uploaded) You lose 10mm on z axis about 20-25 on y and x axis. I designed wheel mounts to squeeze and snap in place using polymax PC don't know how well the design will work with other plastics. I and used Carbon Fiber PETG for mount with four M6 50mm hex bolts and nuts it's about 250gm mount. Most Low powered lasers can be mounted with one m3 screw. drill a a 3mm hole through appropriate level in front of mount. Then mount laser then mount clamp backwards. I have a picture of this on the Bauer upgrade build. Flir images of 35,000rpm no increase in heat from 26,000rpm springs are coiled spring steel, sold as automatic door closers on Ali Express 500gm , remove from square of shell, make sure and crimp a that coil in the center to for a small circle that will slide in the bolt. follow the pictures above, mount them on M8 / 5/16" bolt , drill out 3.5mm hole down center of bolt and slice bolt in a half lengthwise. I also slice the m8 (5/16") nuts in half and convex side touches bearing etc. works as like a lock nut this way and allows the bearing to spin freely. 500gm spring coils https://www.aliexpress.us/item/3256804585142255.html?spm=a2g0o.productlist.main.11.3ecd49221jLXMW&algo_pvid=9b104f05-4e91-4ccd-b1db-69901ddda760&aem_p4p_detail=2023080901525510303530687260820000908962&algo_exp_id=9b104f05-4e91-4ccd-b1db-69901ddda760-5&pdp_npi=4%40dis%21USD%217.37%214.79%21%21%217.37%21%21%402101e9d316915711755282564e82bc%2112000030414892286%21sea%21US%21162043050%21&curPageLogUid=3DVmnHBCPlWx&search_p4p_id=2023080901525510303530687260820000908962_6 T8 2mmpitch 4mmlead nuts are hard to find , will need to screw in bottom for thread of router mount initially I printed file above with Priline super hard PC/CF worked fine while awaiting order. I bought a cheap POM version can order below https://www.aliexpress.us/item/2255799822949999.html?spm=a2g0o.productlist.main.9.c48f70a4TKB0DF&algo_pvid=61d92e1f-63ae-4a83-ab72-03dde65fe1ba&aem_p4p_detail=202308090206549224322391157280000832767&algo_exp_id=61d92e1f-63ae-4a83-ab72-03dde65fe1ba-4&pdp_npi=4%40dis%21USD%210.65%210.65%21%21%210.65%21%21%402103241d16915720143245230e76e2%2110000000025465313%21sea%21US%21162043050%21&curPageLogUid=BxcGr1ROA6T3&search_p4p_id=202308090206549224322391157280000832767_5 bits https://www.amazon.com/dp/B07FSJLMJ5?ref=ppx_yo2ov_dt_b_product_details&th=1 bearings https://www.amazon.com/dp/B09W618C5Z?psc=1&ref=ppx_yo2ov_dt_b_product_details speed controller https://www.amazon.com/dp/B0982X3PLM?psc=1&ref=ppx_yo2ov_dt_b_product_details SSR 10 DA https://www.aliexpress.us/item/3256803923381467.html?spm=a2g0o.productlist.main.3.5b7b3113kwxXPn&algo_pvid=6dcbb2da-6010-4504-a4e6-b6a3a856c2c0&aem_p4p_detail=202308090030374096261855014850017304174&algo_exp_id=6dcbb2da-6010-4504-a4e6-b6a3a856c2c0-1&pdp_npi=4%40dis%21USD%217.40%213.7%21%21%217.40%21%21%402103255b16915662371363095e9e7b%2112000029779325302%21sea%21US%21162043050%21&curPageLogUid=atdjnC8KQIaV&search_p4p_id=202308090030374096261855014850017304174_2

With this file you will be able to print 15$ Harbor Freight Router cutting steel and Milling aluminum , 3018 CNC Upgrade 400watt 45,000RPM, 10newton Z axis assist, with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 15$ Harbor Freight Router cutting steel and Milling aluminum , 3018 CNC Upgrade 400watt 45,000RPM, 10newton Z axis assist, .