20mm Plastic T-Slot

thingiverse

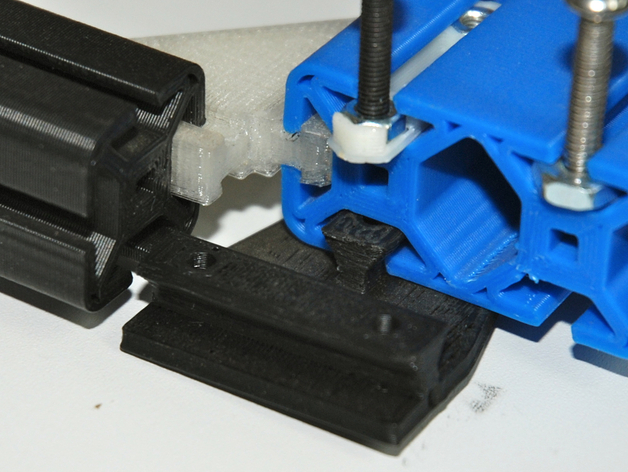

20mm Plastic T-Slot - Rev 2 Completely redesigned; the new beam prints faster and is stronger both against deflection and torsion. UPDATE: Added DXF of Profiles. Naming convention is [dimensions]-[bolt size]-[Wall Thickness]-[Multiplier]. We are starting to prefer 1pt6 (1.6) wall thickness profiles and find printing them No Infill, 1 Extra Loop, No solid Layers, with a trace thickness of .8mm results in a quick and adequetly strong beam. These beams are being designed as the main structural component for a 3d printer though arguably they are of more use as a general hobby framing and mounting set. That said they are designed with both printing and commercial extrusion in mind. If printed in ABS, they can be solvent welded with the aid of a T-Slot Welding Jig http://www.thingiverse.com/thing:13598 and ABS Glue http://www.thingiverse.com/thing:14490 . A center hole increases the beams second moment of inertia while aiding in fusing beams. PLA beams are more rigid though they are not as easy to fuse into various lengths. Hardware An example of Friction Fit hardware is located - Here - http://www.thingiverse.com/thing:9797 & Here - http://www.thingiverse.com/thing:13599 The standard beam profile is meant to accommodate both M3 hardware as well as 6-32 nuts and bolts. Both bolt heads or nuts will fit in the slot with an insert provided to help guide and captive M3 nuts. 6-32 Nuts will captive natively. Alternative profiles are provided for M4 / 8-32 hardware as well as dedicated M3 and 6-32. All profiles are located in "20mm Profiles - Printing.skp" Use the 'Push/Pull' tool to create a profile of the desired length. If the printing instructions are followed, these beams can be printed fast (going at even a moderate pace we're able to produce all the beams needed for a Prusa in under 12 hours). While the beams can technically be printing with any working profile, they will not print as quickly and may not perform as intended structurally. Files 100mm Beam.stl - actual height is 101mm to allow for loss during welding 20mm Test Beam.stl - shorter for testing settings M3 Nut Insert.stl - use with metric hardware 20mm Profile-Printing.skp - profile faces for printing and creating different heights 20mm Profile-True.skp - diagram of a properly printed profile 20mm Profile-Printing-pt4.skp - profiles based on 0.4mm widths, contains a M5 profile M3 Nut Insert.skp - source file for insert Check Back For T-slot Profiles for Thing-O-Matic, Ultimaker & Mosaic at various resolutions, speeds. OpenScad version to ease design of compatible hardware and accessories. Instructions READ ME! These beams are designed with 2mm wall thicknesses to be printed with zero infill using consecutive loops of 1mm trace widths. There are also also a set of beams with 1.6mm walls for .8mm trace widths located in "20mm Profile - Printing - pt4.skp" though the standard profiles are more tested. When printing correctly, the nozzle will trace out 2 (3 for stronger) consecutive loops making a single jump as it jumps layer. The center hole is absent in the profile and created as an artifact of having zero infill. If you plan on printing many of these beams it will be worth your time to create a dedicated profile adjusting Flowrate (or what-have you for your skeinforge version) to give the best looking and strongest beams. General Tips If you go to fast printing a single beam the print can start to mash about from overheating. Use a cooling fan or print multiple beams at once to give each layer time to cool. You can alternatively turn on the 'Cool' plugin to slow everything down...but who wants that, we're making T-Slot! It is possible for T-slot printed in a thingomatic to warp ever so slightly towards the back of the bot. If this happens, enclosing your bots open sides with board or tin foil will help. I have a piece of cardboard that clips to the Z-stage that shrouds to the front of the bot in much the same way as the z-stage shrouds to the back of the bot. This helps the most. If your nozzle is too low on the first layer you will get a small flange at the base of your beam. It can be taken off with a razor or better, change your Z-height slightly to give your nozzle a little more room for that first layer. Profiles are being put together for various printers and extruders for a more plug and play printing experience but the following should help you get setup making a dedicated profile. Settings ReplicatorG 271) Create New Profile a. Top Menu: GCode > Edit Base Profiles... b. Select the Profile you want to start from ie. SF35-Thingomatic-HBP-Mk7 c. Hit Duplicate and name something descriptive ie. T-Slot ABS d. Your done! Skeinforge should open. If it does not, repeat steps 'a' and 'b' selecting your new profile and click the 'edit' button 2) Edit Toolpath Top Menu: Gcode > Edit Base Profiles.. > 'Your new profile' / click 'edit' Under 'Fill' tab - Extra Shells on Alternating Solid Layers = 1 (or 2, just be consistent) Extra Shells on Base =1 (or 2) Extra Shells on Spares Layers = 1 (or 2) Infill Solidity = 0 Solid Surface Thickness = 0 (I find this to make them look nicer) Thread Sequence Choice = Perimeter - Loops - Infill 3) Adjust Width (if necessary) Under 'Carve' - Layer Thickness (mm) = 'Whatever your comfortable with, I use 0.3 so its a little faster than my standard 0.2 or lower) Perimeter Width over Thickness (ratio) = 1 / (the Layer thickness used previously) ie. If I used 0.3 for my Layer thickness, I perform 1 / 0.3 = 3.3333 This ensures that the perimeter trace width will be 1mm Under 'Fill' - Infill Width over Thickness = The same value used in the previous step, in my case it would be 3.3333

With this file you will be able to print 20mm Plastic T-Slot with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 20mm Plastic T-Slot.