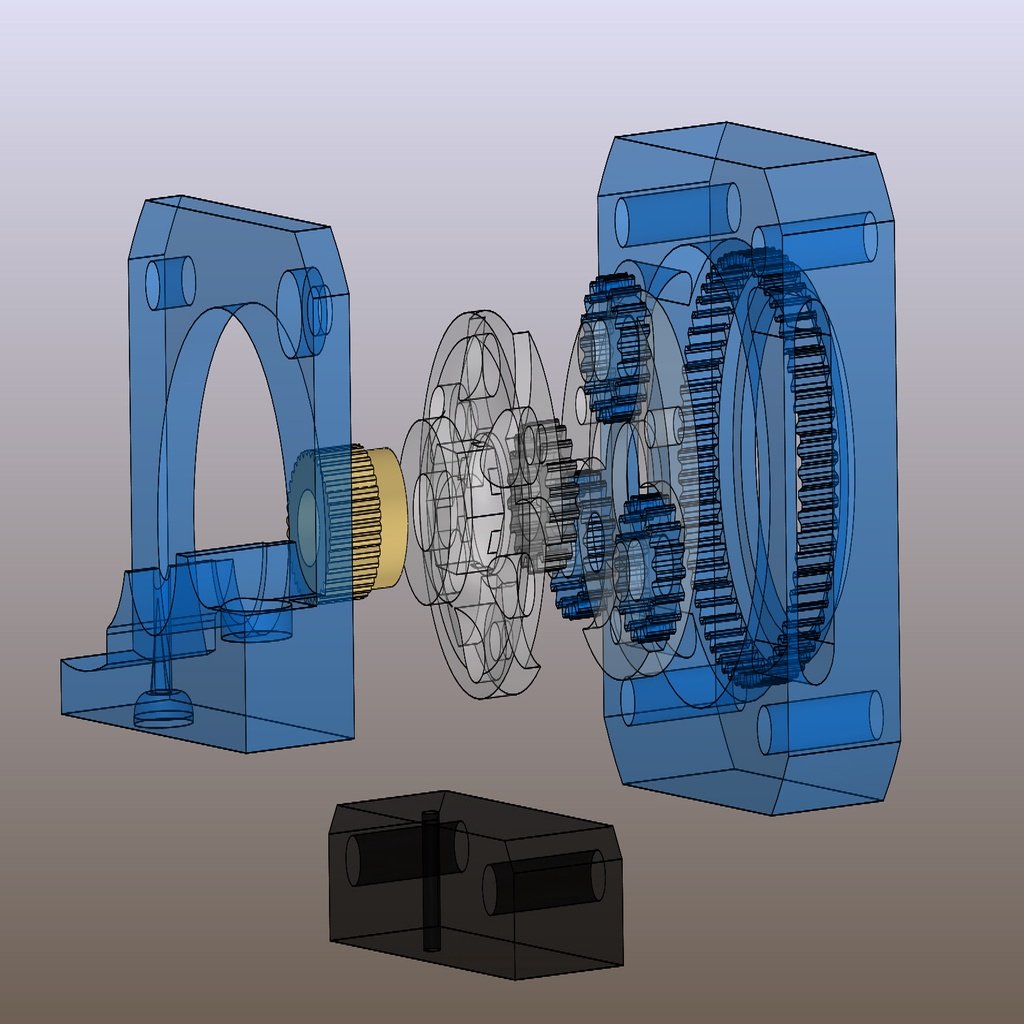

3:1 Planetary Geared Extruder

thingiverse

*** THIS IS A COMPLETE EXPERIMENT TO REMOVE STEPPER PULSES APPEARING ON STRAIGHT WALLS *** I am using this gearbox on 2 machines which I use to make classic bike parts with. Took the E3D theory about stepper pulses on direct drive extruders being removed from the print by making the motor rotate more & gearing down, I also took my planetary gearbox from my large printer project Frankie as this does the job in a small amount of space. There is an advantage in weight reduction as the std extruder motor can effectively be halved in size (Nema 17 42x42x20). Supports not required on all items, I used bridging function for the gear clamp ring instead. Version 2 items are designed to use ballraces MR52 2x5x2 2off each for planet gears. 9mm guide is for cutting the motor shaft & output bolt (when fully fitted) to length only! Update V3 Parts - Changed pinion gear, carrier & output shaft to take larger bearings as the pinion shaft is longer & too much play without bearings. 2off bearings are 11x7x2.5. This also re-inforces the D drive against the shaft. Planet Gear V2: introduction of bearings Added pinion gear for smaller motor without recess or full length D drive to cater for extended D drine on the pinion.

With this file you will be able to print 3:1 Planetary Geared Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 3:1 Planetary Geared Extruder.