+30mm Y-Axis Endstop Extension for Wanhao Duplicator i3 with 8x10 Glass Bed

thingiverse

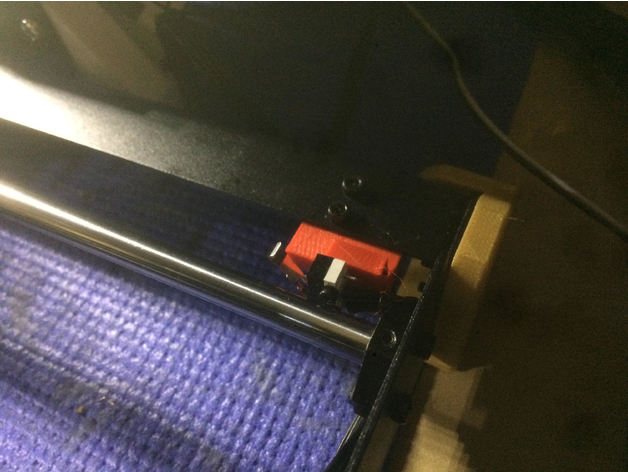

I had ordered a Borosilocate glass plate but it was warped (seems to be a common issue). Found a 8x10" glass plate for $2.20 at HomeDepot and it was flathttp://www.homedepot.com/p/8-in-x-10-in-x-125-in-Clear-Glass-90810/202091040 That plate fits right between the bolts on the heat bed but sticks out a bit at the back, so why not print on that new space? ;-) The corners on the glass plate are very sharp, sand them down with sand paper and clean the plate. To install the glass plate you need to place 1" squares of heat sink (https://www.amazon.com/gp/product/B007PPEW52) on the plate. I put them on top of my stock builtak plate. Most likely your builtak is already warped or has bubbles, just try to not put the strips on any "high spots". One side of the heat sink is more sticky than the other, put that side on the builtak. Put hairspray on the glass plate, let it dry and then place the glass plate on top, align between the bolts left and right and align the front of the glass with the heat bed. The rear will stick out a lot. Level your bed again, you might have to move the z-axis switch up a notch in the bracket. This y-axis bracket moves the micro switch 10mm further to the back which will basically give you 10mm extra space in the front of the plate. There is another 20mm at the rear of the plate that can now be used. I printed with 100% infill. Tap the holes with screws first, insert the microswitch before mounting it to the frame, then carefully test to make sure nothing hits when homing the Z axis, especially if you have custom belt tensioners. Then change the "Y max length" setting in the EEPROM, I used octoprint (great tool!) with the EEPROM Repetier plugin. Position the Z-axis to 220mm, disable the steppers and check how much more free room you have before hitting the end stops. Then repeat at 225mm and finally 230mm. At 230mm I only have 1mm before hitting the end stop. Update the printer settings in your slicer and do a test print with objects in the far corners. Cura 2.4 has a 2mm "offset" as well so if you want to print to the edge you need to increase your size in cura http://3dprinting.stackexchange.com/questions/645/cura-not-allowing-full-print-area-to-used Btw, printing on glass is awesome, the bottom of the printer are super smooth and the objects just pop off the plate once it has cooled down. Still have to work on a couple of things: lost a few mm on the left, might have to adjust the x-axis sensor or change firmware settings to start printing a few mm to the right. Maybe use the glass plate as a "nozzle wipe"? the heatbed cable rubs on the glass plate, need a bracket to or rotate the heat bed 90 degree and use a cable chain.

With this file you will be able to print +30mm Y-Axis Endstop Extension for Wanhao Duplicator i3 with 8x10 Glass Bed with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on +30mm Y-Axis Endstop Extension for Wanhao Duplicator i3 with 8x10 Glass Bed.