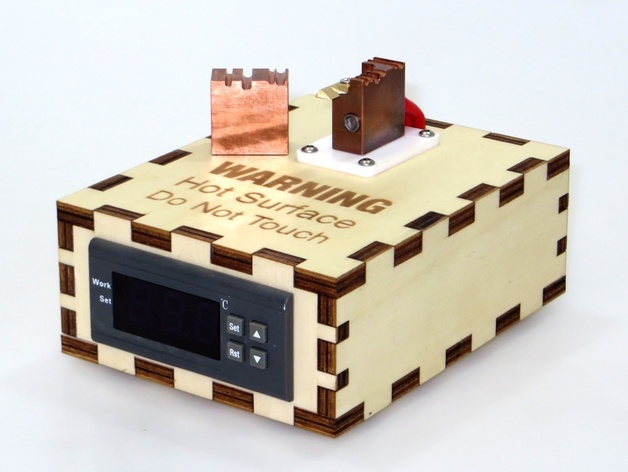

3D Filament Splicer

thingiverse

This is a small tool we have created for splicing 3D Filament. It is suitable for 1.75 and 3mm filaments. Actually quite a lot of work went into it this 'little thing', we tried to make fully automated splicer first but it failed due several issues such as filament expansion / shrinkage. So manual labor is still the king :) On the filament sample snapshot you can see results, 1 is manual and 2 is done with splicer. Of course you can trim manual joint but it is work and will get annoying soon enough. You can get Splicer copper parts, kit or fully assembled unit via our crowdfunding campaign. We work to bring more color options to OSS 3D Printing and have a few other very interesting ideas. Filament Splicer is first tiny step in this quest. Instructions Bill of materials 6mm plywood frame (see Blueprints) Teflon / PFTE thermal isolation plates, minimum 5mm (see Blueprints) Copper heating and cooling blocks (See Blueprints) 12v thermal controller from Willhi 300c thermal probe with 4mm diameter Cartridge heater 12v 5mm socket, we use high quality metal connector with 10mm neck on/off switch with 12mm neck and M3 terminal screws 12v 6A Power supply 0.5 mm2 wires 4 x 20mm M3 Screws with matching bolts 2 x 7mm M5 Screws with countersunk heads 2 x crimp-on 3mm terminals (Optional for Switch connector) Fast setting wood glue Rubber feet Notes: There is a M3 hole on the top of the heating block, it is for hot knife fixation, there is no blueprint for it, we manufacture it by hand from brass profile, your choice of form. It helps to have a V-Groove in it for easy removal of excess plastic. See pictures of out final product. Thermal isolation plate for heating block should have drilled impression for countersunk screw head to go in. The less hot metal is under the PFTA, the better. Otherwise wood will start charring with time. Box is glued together, it is actually very simple job and our wood glue sets in within 15 minutes. We advise to cover box in protective oil as we do with out kits, otherwise it will get dirty very soon. Do not ever exceed safe operating temperature of PFTA plates (260c in case of our material specs), Teflon emits very nasty fumes when overheated.

With this file you will be able to print 3D Filament Splicer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 3D Filament Splicer.