3D printed alpha Stirling engine

thingiverse

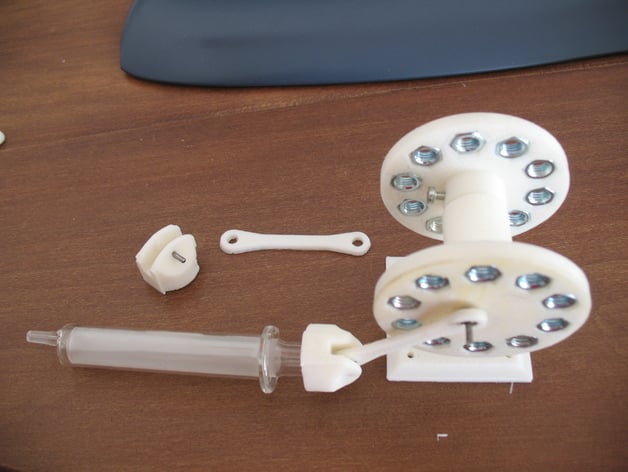

2x5ml glass syringes 20xM6 nuts 2xM3 bolts one 3 mm rod axis 4 pieces of 2mm rod 4x2mm ball bearings 2x3mm ball bearings several PLA meters !!! 2 pieces of wood one candel 10 cm of 3mm ID silicon tubing and you get a (not yet) beautiful, fully functionnal 3D printed Stirling engine. Just see it on youtube: http://youtu.be/NecriSICN7w edit : please see the #2 motor here : http://www.thingiverse.com/thing:278422 Instructions All part are printed in PLA using Slic3R with an infill density of 0.5. All holes shall be drilled to exact diameter: main axis = 3mm seringe heads and whell pin = 2 mm main axis ball bearing = 6.5 mm head rod ball bearing = 5 mm Before printing the inertia wheels, I would advice to first print 2 test pieces (M3 and M6.stl) to check that the nuts fits correctly into the holes... Adapt the size in .scad files... The M6 nuts are needed to give some inertia to the wheels. They fit smoothly into the hexagonal holes. If you get some play, just use a soldering iron to melt the PLA lip and seal the nut in right position. The syringes head also fits smoothly into the plastic head and can be easily unmounted. see http://youtu.be/fF49rg12fj8 The syringes pistons shall be run in using car repair very thin sand paper. Support of the two seringues cannot (a shame) be printed as the syringe body may become quite hot ... I've to find a way to print something using some thermal insulation... By now, I must admit my wooden support is uggly, I just wanted to make a first demonstration of the proof of concept !

With this file you will be able to print 3D printed alpha Stirling engine with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 3D printed alpha Stirling engine.