3D Printed Hand Automatic Scaling Tool - 3D PHAST

thingiverse

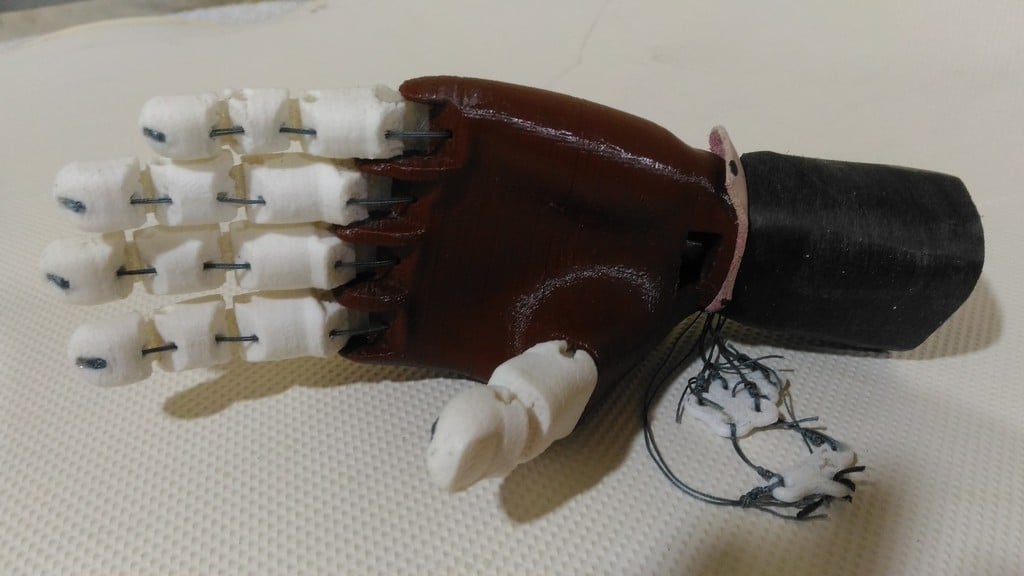

This excel generates the parts for a 3D hand prosthesis to be attached by a bolt to the patient's arm socket. This tool was created with several purposes in mind. Firstly, it allows the user to adapt the prosthesis size to their hand size, reducing the visual impact of the prosthetic. The prosthetic hand is joined by a standard bolt to the arm socket produced in FUNPROBO with the 3D print hand prosthesis. This arm socket is manufactured by mold from the patient's arm and is strong, reliable, and comfortable since it is personalized for the user. Secondly, the hand and arm are independent, making it easy to replace one or both if they become damaged or need to be replaced. The tool consists of an xlsm file with a macro that should be filled in order and pressed to generate the files. These excels generate Openscad files that modify the STL reference files and create the STL ready to print. To create the STL ready to print, you only need to double-click the .bat file generated with the openscad files. The 3D model will have the patient's hand size and be ready to be bolted to the arm socket. I created this tool during a volunteer program at FUNPROBO. This NGO is located in La Paz and provides free prosthetics to Bolivian amputees, offering them a chance to work again and regain independence. FUNPROBO manufactures locally in La Paz all kinds of leg prosthetics and trains the amputees with physical therapy for their correct use. The organization works thanks to an amazing staff and volunteers coming from all over the world. Please check the website to see the encouraging patients' stories, and I recommend liking the FUNPROBO Facebook site to stay updated on the daily progress. If you like this initiative, there are many ways to collaborate with them, including checking the website to learn how or donating through the Facebook website. Looking for an affordable way to create hand prosthetics for arm amputees, we decided to create a 3D printed hand prosthesis to be bolted to the arm socket. The arm socket is manufactured by FUNPROBO prosthetists technicians from patient arm mold and fits perfectly to the patient's arm. It is stronger and quicker to produce than the 3D printed solutions. The hand is based on a full palm version of Flexyhand, modified with new wiring tubes. The Openscad files escalate the reference files and perform geometric modification to create support and the nut pocket, which are executed by a .bat file producing STL ready to print. Excel should be filled with the measurements of the patient indicated in the pictures, and some parameters can be modified for more personalization. This tool generates the STL files of a hand prosthesis with the following features: The tool uses the user's hand size to generate the prosthetic parts. The prosthetic hand is attached to the arm socket by a standard bolt. The arm and hand are independent, making it easy to replace one or both if they become damaged. You need to check that openscad installation path is right, 00_references_models path is right, input the measurements of the hand, input the nut size (better if you let the automatic size), run the macro, run the .bat file and wait for all STL to be created. The models generated are based on Flexyhand and Flexyhand2 by Gyrobot and full palm by Adolph. Rigid material like PLA or ABS should be used for Hand, Fingers, Nut cover, and Thumb. Flexible material like TPU93 is recommended for Hinges, as some flexible materials are not rigid enough to move the fingers back after wire tension is released. TPU93 is rigid enough and reliable for this use. The big hinges between arm and first finger phalanx should be curved, assembled pointing outward to increase the springback. Check the correct position before assembly. The nut hole is created with supports inside, which should be removed to insert the nut. Self-locking nuts are recommended but can be tricky to tighten. This tool was created by Juan de las Heras and you can contact him at Jdelasheras83@gmail.com.

With this file you will be able to print 3D Printed Hand Automatic Scaling Tool - 3D PHAST with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 3D Printed Hand Automatic Scaling Tool - 3D PHAST.