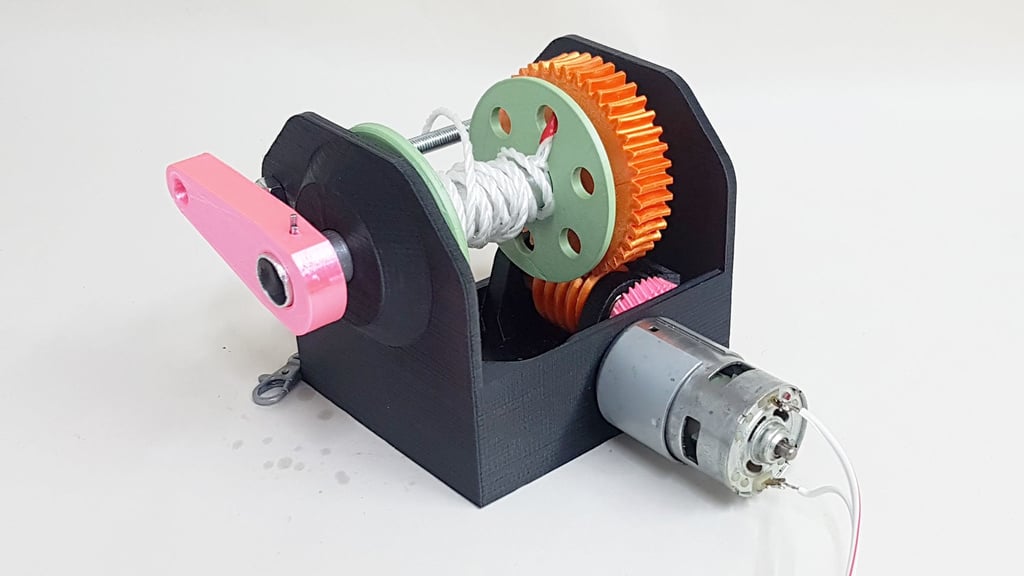

3D printed high torque gearbox – Building an electric hoist – worm gearbox

thingiverse

Video link: https://www.youtube.com/watch?v=yV8tZ1epLHU Source Files:https://www.cgtrader.com/3d-print-models/hobby-diy/mechanical-parts/3d-printed-high-torque-gearbox-worm-gearbox-electric-hoist More details:https://hackaday.io/project/178194-3d-printed-high-torque-gearbox-an-electric-hoist I made this 3d printed high torque worm gearbox. It called also winch, hoist or crane. The gearbox uses a 775 12V 13000 RPM (100 Watt) brushed DC-motor which it has 0.074 Nm torque and 13000 rpm. This 3d printed gearbox had a gear ratio of 98:1. So the torque on the output shaft became 7.3 Nm or 75 kg*cm and the speed of the output shaft was about 132RPM with this gearbox. (in theory) I used PLA+ in all parts. The output shaft is 20 mm in diameter and thus the maximum force the gearbox can lift is 737 newtons. (75.1 kg) Since the friction of the rope would be high, I assumed a 10% loss. but this is only valid when a rope is used. If we use the torque lever on the side, there will be no such loss. The helical gears I used have a 1 mm module and a 23 degrees helix angle. I chose a low helix angle to avoid too much axial force. The pinion gear on the motor is 13 teeth and the counter gear is 34 teeth. Thus theoretically the gear ratio in the first stage is 2.61. There is also a worm gear on the same shaft. The worm gear I used in this project has 40 teeth. So the gear ratio in the worm gear mechanism is 40. Here there is a really high torque increase in one stage.The shaft I use here M8 threaded rod. I used 608zz roller bearing for bearing the shaft. Output shaft has a 20 mm diameter and I used 2x6004(ORS) roller bearing to support. I was able to test the gearbox to a torque of about 43 kg*cm.During testing none of the gears broke, they were all printed in PLA. At the first car test, the gearbox could not fully pull the car because the road was bumpy. At the same time, the rope broke. Then I went home and I do not give up:) Because I knew the gearbox could pull the car. Theoretically this was possible and as you can see in the video…I do not recommend using it in the professional field. Because you can't trust to plastic parts! Regardless, it was a very entertaining project. Below are all the parts I used in this project: -12V DC 775 Motor(100 Watt) -608zz bearing x3 -6004 bearing x2 -20 mm aluminium shaft -M8 threaded rod -Cotter pins --2x30—x4 --3x50—x1

With this file you will be able to print 3D printed high torque gearbox – Building an electric hoist – worm gearbox with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 3D printed high torque gearbox – Building an electric hoist – worm gearbox.