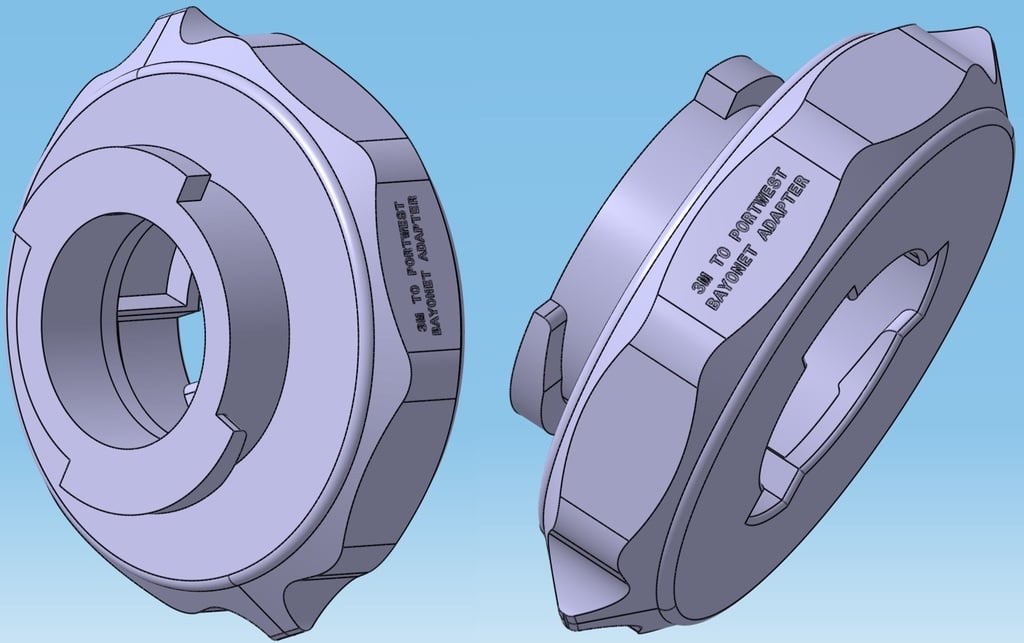

3M™ Bayonet to Portwest® Bayonet Filter Adapter

thingiverse

3M™ Bayonet to Portwest® Bayonet Filter Adapter ======================================= This was originally a proof of concept, but now updated to prototype design for a 3M™ to Portwest® bayonet to bayonet filter adapter as requested recently by Daramcgrath. I do not have Portwest® respirators or filters and used scaled pictures online of Portwest® bayonet to approximate bayonet dimensions. Will need support from 3D printing community in UK and Europe to prototype this and comment on fitment in order to revise dimensions for Daramcgrath. As an update, Daramcgrath was able to print the proof of concept and after conferring on geometry demonstrated bayonet geometry is correct. Part Description: ============== 3M_BAYONET_TO_PORTWEST_BAYONET_PROOF_OF_CONCEPT_ONLY.stl Initial model with rough Portwest® bayonet geometry from scaled images alone. 3M_BAYONET_TO_ASOSAFETY_THEAD_ADAPTER_GEN2.stl Gen. 2 features the following: (1) chamfers added to 3M bayonet to filter mating surfaces to reduce sharp edges that could result in wear on 3M bayonet, (2) redone chamber from underside OD to wrench flats to reduce printing overhang supports, (3) added engraved markings on exterior periphery to ID adapter, and (4) OD of bayonet changed from estimated 31.5 mm to 33.5 mm, bayonet thickness changed from 2.5 mm to 3.0 mm, and on the base/cylindrical extrusion diameter changed from 27 mm to 28 mm. 3M_BAYONET_TO_PORTWEST_BAYONET_ADAPTER_GEN3.stl Gen 3 model features the following changes: (1) completely reworked 3M bayonet to filter geometry to ensure proper fitment/compression against OEM gasket in locked position, (2) reduced OAL of adapter and (3) chamfered 45 degrees to the wrenching ears to remove printing overhangs. Disclaimers/Risks: ============== 1.) This is a proof of concept only – model in work. [UPDATE - Now Prototyped] 2.) Use Proper Gaskets Requires gasket or o-ring on the underside bayonet to ensure proper seal maintained between cartridge and bayonet. 3.) Perform Proper Negative Pressure Test Follow SSPs established by your institution or workplace for further guidance. But in general, don your respirator, adjust straps till taught against face, ensuring no obstructions around the periphery of the seal against face either due from hair, facial hair, or otherwise. Exhale deeply. Cover all inhalation ports. (Typically, most full face or half face respirators have two filters, so cover those intake ports with your hands. If your running only one filter, ensure the opposite port has filter cap in place.) Now inhale deeply. The mask should suck tightly against your face without any air leakages. Re-test if adjustments are required at gasket/o-ring interfaces at the adapter. 4.) Use At Own Risk – Temporarily Solution Only Until Supply Chain Normalizes 3D printing materials are not resistant to many solvents, are water soluble, and degrade when exposed to chemicals, heat, and UV/sunlight. 3D printing this adapter is only a temporarily ad-hoc solution against biological contagions. In addition to using a properly calibrated 3D printer, due to tolerances of adapters, if possible perform hot nozzle pass on all exterior surfaces, to reduce surface porosity. Highly recommended users apply a thin layer of polyurethane clear coat on all exterior surfaces, spray or dip based methods, to help resiliency and durability for repeated sterilization and to reduce fomite transmission in printed infill layers. Once supply chains return to normal, users should purchase OEM OSHA/NIOSH/EN standard approved respirators, adapters and accessories for their institution and workplaces. Dev. Notes: ========= 04/11/2020 - Initial model release. In work, pending support and feedback from UK and European 3D printing community for any fitment and model revisions. I do not have Portwest® respirators or filters to check measurements. 04/13/2020 - Revised model based on feedback from Daramcgrath, measured ID of 35 mm and on the 30 mm on bayonet, filter female side. The following changes have been made: (1) chamfers added to 3M bayonet to filter mating surfaces to reduce sharp edges that could result in wear on 3M bayonet, (2) redone chamber from underside OD to wrench flats to reduce printing overhang supports, (3) added engraved markings on exterior periphery to ID adapter, and (4) OD of bayonet changed from estimated 31.5 mm to 34 mm, and on the base/cylindrical extrusion diameter changed from 27 mm to 28 mm. 04/22/2020 - Confirmed with Daramcgrath that the bayonet geometry interfaces well with the Portwest® filters. 04/28/2020 - Gen 3 model features the following changes: (1) completely reworked 3M bayonet to filter geometry to ensure proper fitment/compression against OEM gasket in locked position, (2) reduced OAL of adapter and (3) chamfered 45 degrees to the wrenching ears to remove printing overhangs. Credits: ======= Special thanks to Daramcgrath for taking the time to pull the geometry on the filter side to ensure mating bayonet surfaces are true.

With this file you will be able to print 3M™ Bayonet to Portwest® Bayonet Filter Adapter with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 3M™ Bayonet to Portwest® Bayonet Filter Adapter.