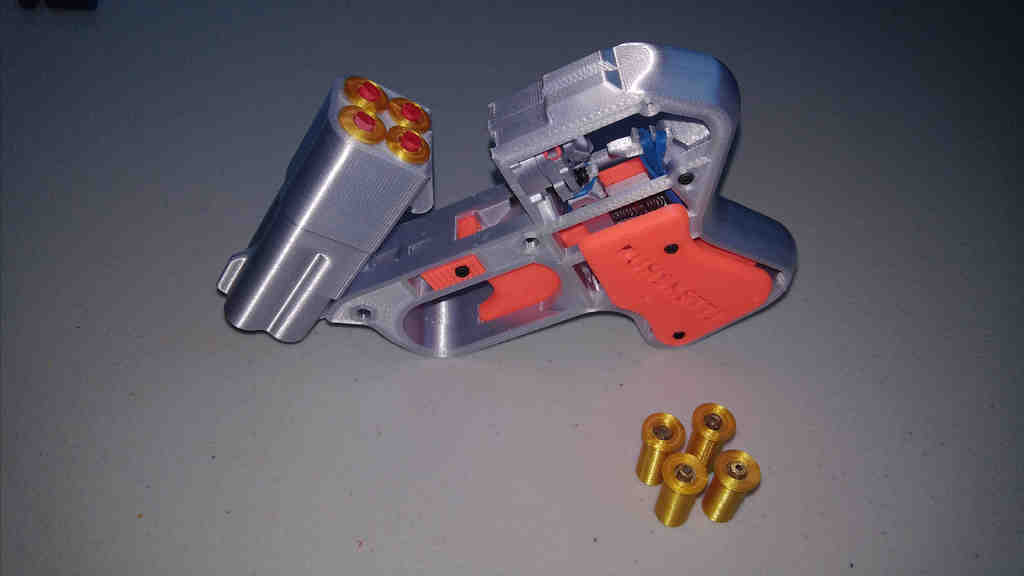

4-BARREL DERRINGER CAP GUN TOY

thingiverse

Made the files free! Thank you for everyone who purchased this. It really helped me through a hard time! Build video: https://youtu.be/Fe_tGZ5SJdc Check out some videos of the toy working here: https://www.instagram.com/puhsketti_prints/ UPDATE /June 15, 2020: I have made some changes to the skeleton frame pieces and the hammer_head to increase the strength of a thin section. UPDATE /June 11, 2020: I have found an issue with the original hammer_head.STL file and have updated it. If you downloaded the files before June 11, please download them again and use the new part called hammer_head_shorter_fins.STL in the Internals folder. A toy based on 4-barrel configuration derringer pistols. The toy features a functional dual-action trigger mechanism. The toy requires 3 common steel springs, two elastic rubber bands, 17 M2 hex socket cap screws, 7 M2 nuts, and 4 M2 washers. For ammo, I use common plastic strip caps. More detail is provided in the files. This is not a real firearm and cannot function as such, Makers should be cautious and check with their local laws before downloading the files. Please observe all local laws when making such an item. Use this model at your own risk! Do not try to fire real ammunition! I am not liable for any use or misuse of this model! When assembling, make sure all moving parts move freely. Do not over tighten any screws! This project REQUIRES quite a bit of skill, tinkering ability, and a very well tuned printer. I cannot guarantee that you can make this item fully functioning. I DO guarantee that the files are printable and even if you don't get the trigger functioning properly, you will have a cool display piece if nothing else. WEAR SAFETY GLASSES AT ALL TIMES WHILE ASSEMBLING AND PLAYING WITH THIS TOY!!!!!!!!! NEVER POINT A TOY GUN AT ANOTHER PERSON, YOURSELF, OR AN ANIMAL EVEN IF IT IS UNLOADED! POP CAPS AWAY FROM YOUR EARS. HEARING PROTECTION IS ALWAYS A GOOD IDEA. Required materials: 1.) Filament of your choice! PLA and PETG both will work well for all of the parts. I have mainly used PLA for these toys and have had no real issues with the material. Check your local laws about cap gun toys before making color selections. Most places require a bright orange tip on the barrel of the toy, or the toy to be manufactured from brightly colored plastics. I have just used a simple "filament swap" technique for the top 5mm to 21mm of my barrels to give them an orange tip. 2.) printed parts: 1x left frame (choose between the skeleton frame and the solid frame. I have done a lot more testing with the skeleton frame and it is easier to print and easier to trobleshoot, so I recommend starting with the skelton frame.) 1x right frame 1x barrel (choose a barrel. there are several variants including 125mm barrels or 75mm barrels) 1x left grip (there are several grip variants included) 1x right grip 1x hammer arm 1x hammer head 1x hammer spring inner 1x hammer spring outer 1x hand 1x latch_L 1x latch_R 1x rachet 1x rachet_arm_stop 1x sear (if the regular sear does not function correctly for you, there are several others provided in the Experimental_parts folder" 1x trigger 4x(or more) ammo shells (choose betwwen all-plastic ammo shells or ammo designed with an anvil insert made from metal tubing) 3.)screws/nuts/washers: 4x m2 washers 7x m2 nuts hex socket head cap screws: 4x m2x10mm (FOR THE FIRING PIN, I HIGHLY RECOMMEND USING A 8MM SCREW, BUT A 9MM OR 10MM SCREW WILL ALSO WORK. THE SHORTER SCREW GIVES MORE CONSITENT FIRING PIN POSITIONING) 6x m2x15mm or 16mm 4x m2x20mm 3x m2x5mm 4.) springs: 3 springs are required. I used the "Everbilt Spring Assortment Kit (84-Pack)" from my local Home Depot, but similar metric and imperial springs should be easy to source elsewhere and should work fine. hammer spring: (diameter=11/32in, length=1in , wire diameter=~0.5in) OR (diameter=8mm, length=25mm, wire diameter=~1mm) trigger spring: (diameter=11/64in, length=1.5in, wire diameter=~0.2in) OR (diameter=4mm, length=35mm, wire diameter=~0.5mm) barrel latch spring: (diameter=11/64in, length=5/8in, wire diameter=~0.01in) OR (diameter=4mm to 6mm, length=15mm, wire diameter=~0.3mm) 5.) rubber/elastic bands: I got my rubber bands out of a small assortment pack from my local office supply store. 1x rubber band cross section: ~(1.5mm x 1mm) unstretched/uncut length: ~85mm 1x rubber band cross section: ~(3mm x 1mm) unstretched/uncut length: ~65mm 6.) The ammo requires caps! I like "star caps" plastic strip caps because they are easy to find and cheap, but pretty much any other plastic caps should work just fine. 7.) optional but recommended: 3.5mm OD x ~1.5mm ID metal tube (brass or stainless steel or any other metal should work fine) cut into ~10mm lengths. This is for making more durable ammo for the toy. The all-plastic ammo's durability relies heavily on the imact strength and layer adhesion of the filament used. Using metal tubing for the anvil will help the ammo shells last a lot longer. The only source i could find for this diameter of tubing was "uxcell 3.5mm OD 1mm wall thickness brass tube" on aliexpress. It may be possible to use 4mm OD tubing instead, but i personally havent tested that(I ordered 4mm tubing several months ago but it never arrived). There's an STL for 4mm tubing ammo in the Experimental_parts folder. Superglue is helpful for securing the metal anvils in the plastic ammo shells, securing orange tips to the barrels of the toy, or if you need to repair any damaged printed parts. White lithium grease is very useful for lubricationg moving parts. 3D PRINTING SETTINGS Models are optimized for a 0.4mm nozzle, 0.4mm line width. and 0.2mm layer height. Supports are required and should be set to "everywhere" in your slicer. Use a support roof. I recommend a support roof of 0.4mm thickness at 90 to 100% density. Cura's support settings "fan speed override" and "supported skin fan speed are useful for getting easier to remove supports. PLA and PETG should work fine in all parts of the model. I used a wall thickness of 1.2mm and a infill percentage of 20% for most parts. I recommend printing the sears with a wall thickness of 3mm so they are more durable. Parts should import into your slicer in the correct orientation! I don't recommend any other print orientations. Z-seam location should be set to inside corners. For cylindrical parts like the ammo and the barrel, i recommend aligning the seam for better surface finish.

With this file you will be able to print 4-BARREL DERRINGER CAP GUN TOY with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 4-BARREL DERRINGER CAP GUN TOY.