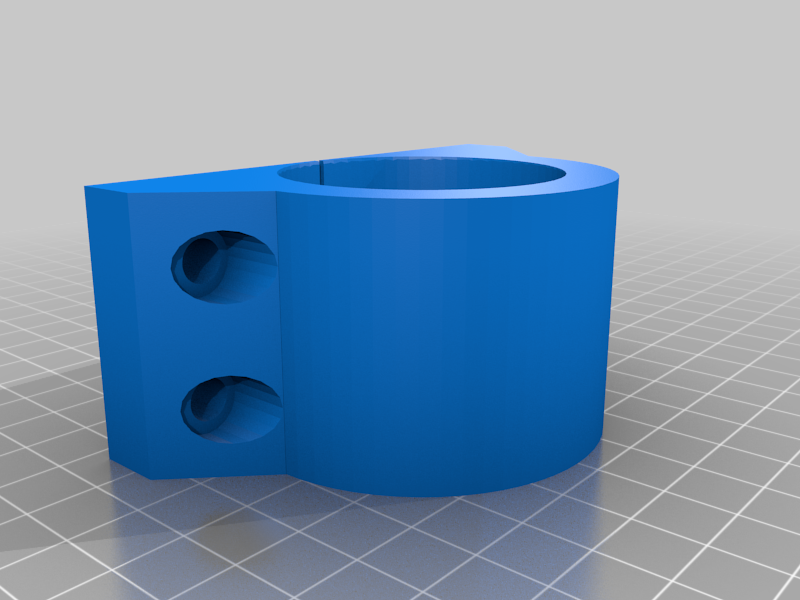

43mm spindle motor mount for cnc engraver

thingiverse

For a 43mm motor diameter attaching to a 70mm M6 bolted mount, with the goal being to reduce all margin between mount and motor. I also wanted to keep the design ultra-simple, without the need for multiple parts or additional screw/nuts. This part worked perfectly for me, but there is very little tolerance for mistakes, and it will require some torquing to get things fit and bolted down. My belief is if the part is under tension, using CF-PLA, it will have less flex. I didn't use Nylon-CF as I didn't want to worry about moisture absorption. So yeah, screw mounting is for M6, but I'd recommend 25mm to 40mm screws. If you use too short, it will be hard to bolt in as the tension around the motor comes from the bolting process. If you try to bolt in with 10mm, you'll find the bolts don't go in straight enough to work. Bolting spacing is about 70.3mm apart, with a 1mm flex gap for the motor to be pressed / torqued in however you want. When bolted into the 70mm expected position, this tightenings and very firm holds the spindle in a compressed state -- that 0.3mm goes a long way. You may need to adjust things, but this fit my 775 3018 spindle, but just barely. I used 40mm M6 screws, which worked well for me. If the motor is slightly too small, you can apply some tape I guess as a shim. I printed upright, with the print contouring the circular outline. This had the layers facing the strongest direction, as if you print this on the side, the layers may tear apart when under tension. I also printed with Carbon Fiber PLA, with 100% infill, and it was done in a single night with about 100g of filament used. My nozzle is a 0.6mm tungsten volcano in a heated print chamber to avoid warping. Reason for this part -- I bought a new 775 motor and some golden/yellow looking z-axis from Amazon. The mounting for the z-axis is 70mm though. I also wanted to have a design that had zero added padding, as I don't want to increase the leverage forces on the motor. I have a small cnc for milling steel, but the 3018 (1610, in fact) is perfect for my carbon-fiber milling. It fits in a transparent bin I got from walmart and takes up very little room. All it really needs to cut carbon fiber is a new bit designed for CF milling and very slow cutting speeds/depths. This object was made in Tinkercad. Edit it online https://www.tinkercad.com/things/0Fl6s186dpM

With this file you will be able to print 43mm spindle motor mount for cnc engraver with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 43mm spindle motor mount for cnc engraver.