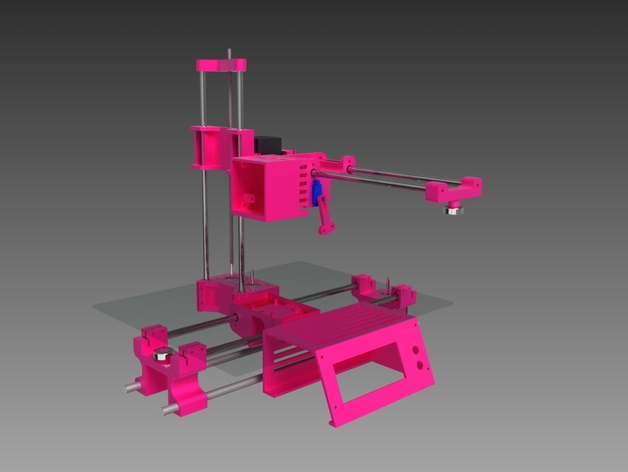

A different Smartrap

thingiverse

After exploring various options, I decided to purchase a Smartrap kit. Upon assembly, I realized that despite its great design and functionality, it had some flaws regarding precision. To rectify this, I redesigned the printer for improved robustness, adaptability, and accuracy by incorporating bearings and timing belts. The Y-axis is now expandable, and additional modifications can be made to X by altering Mode 2 and printing another Mode 5 support (cropping or using a second stepper motor housing for a second extruder). This project is still a work in progress with parts subject to change before completion. All advice and recommendations are welcome. An update was provided as printed parts were tested, revealing minor modifications, mostly cosmetic, and extra room for bearings. The final assembly and testing will occur soon, followed by a YouTube video showcasing the printer's performance. Makercoast, known for their exceptional printing quality and customer service, printed the parts for me. The printer was assembled, and it will undergo testing the following day. Modifications were made to Mode 5 and Mode 10 to address issues with holding the X-axis straight. The original design called for attaching the Y-axis directly to Mode 5, but this was changed after taking pictures. The wire management will be improved once everything is calibrated and working properly. In response to questions, modifications made to ensure smooth operation were detailed. The printer functions well, though it requires bolting to a board for stability. Odd parts, such as a 50mm heatsink and a 60mm fan, were used in the design. The fan shroud's upper tabs were trimmed for easier nozzle access. The printer has its limitations, particularly with printing speed due to X-axis vibration. A solution involves modifying the axis support and X-axis piece to connect them with a nylon cable. Original files in Inventor 2014 format can be shared upon request.

With this file you will be able to print A different Smartrap with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on A different Smartrap.