A Simple Bowden Tube Guidewire Fix

thingiverse

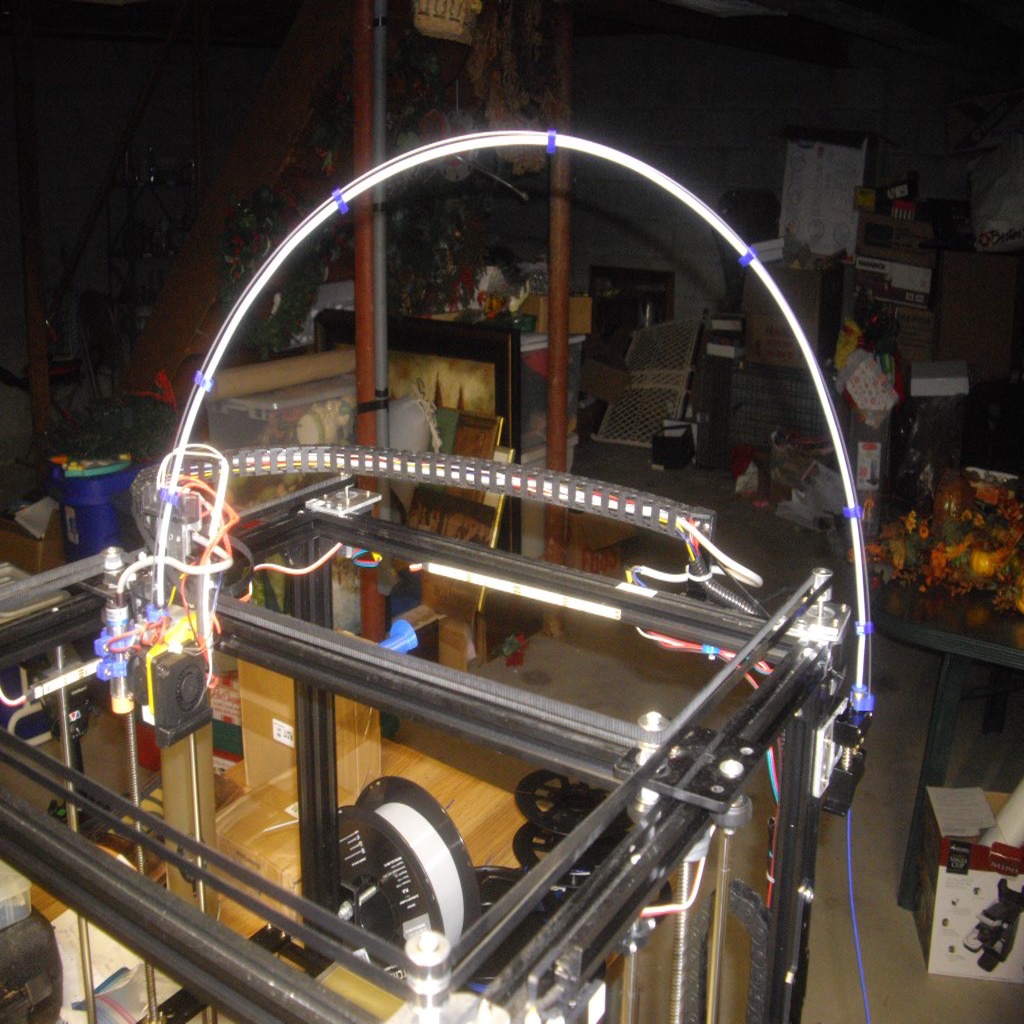

After I replaced the BOWDEN tube of my X5S printer, i noticed that it flopped back and forth a lot. I also noticed that I would get what looked like under-extrusion sometimes randomely occuring throughout a print. There was also 'ground filament' accumulating around the extruder gear. After some time trying to increase the extruder current and running repeated extruder calibrations, I finally realized that the bowden tube would sometimes take on a somewhat sharp bend near the output of the extruder. It turns out that an overly tight bend of the Bowden tube causes the filament to bind up inside the tube casusing all of the above symptoms. In order to control and prevent FBTS ('Floppy Bowden Tube Syndrome'), I came up with a simple piano-wire guide-line and a few bowden-tube-clips that work in concert to keep the bowden tube moving smoothly at all locations about the XY stage. Although I developed these parts to help out my TRONXY X5S printer, it should be adaptable to any Bowden tube machine. All that is required for this upgrade is two 3D printed part designs plus a length of Piano-wire, about the same length as the Bowden tube itself. One printed part (Qty Requred: 2) clips around each of the 10MM hex nuts that make up the tube fittings found on the extruder and hot-end. These provide an anchor point for each end of the length of piano wire (by the way, I used .05 in diameter steel piano wire that I bought an ACE hardware store here in the U.S.). The second printed part is a simple clip (Qty Reqired: 4-8) that snaps onto the bowden tube itself and features a small hole that feeds onto the guide-wire (aka: piano-wire). A few of these (I use 7 of them) should be printed and then placed along the length of the Bowden tube to link the Bowden tube to the guide wire. You can slide them along the length of the guide wire to find the best place for each one, just being sure that no tight radius bends in the tube can occur as the XY head moves through its total range. Then, as the Hot End moves in X & Y, the wire guides the motion of the bowden tube in a way that prevents any tight bends from occuring.

With this file you will be able to print A Simple Bowden Tube Guidewire Fix with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on A Simple Bowden Tube Guidewire Fix.