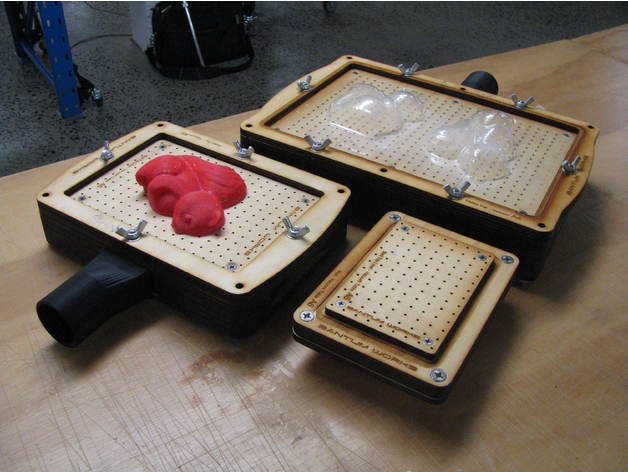

A6 / A5 / A4 Vacuum Formers

thingiverse

A6 / A5 / A4 Vacuum Formers ... These Vacuum formers are basically an enlarged version of a Vacuum Former made by aether ... ( see Remix Link For Original ) I liked the concept, but wanted a bigger Platen area - so they : Are made to fit an A6 / A5 / A4 sheet ... Larger sizes have added extra strength internally ... Require a Hose adaptor to suit regular vacuum cleaner hose ... For ease of fixing are held together with Wing Nuts & Screws ... Easy to make & use ... :) I also had requests for larger machines, so have added two more sizes ( A5 / A4 ) to the original A6 Vacuum former, which are based on a similar concept - but slightly modified to suit duct work entry to the side ... ;) Made to fit an A4 / A5 sheet ( without cutting the sheet ) ... Revised internally ( added stronger ribs / ends ) ... Added a Hose adaptor to suit ... Made some alternate A5 layouts to enable more efficient cutting - Also tried using different materials like foam ... ( will see how they turn out - TBA ) Cheers, Bantum ... Print Settings Printer Brand: Up! Resolution: Fine Infill: 90 to 100 % Notes: For various printed parts ... How I Designed This Drawn up in AutoCAD, 3D Modelled in SketchUp, Laser Cut files edited in Illustrator / Corel Draw ... The prototyping has been all about finding the most efficient use of materials / layout - Also been experimenting with various hole sizes in bed ... Welcome to receive some feedback from users to make further improvements ... More work is yet to be done on using alternate construction materials - testing in progress using dense foam ... Materials Needed Hardware Components : Laser Cut Frames. ( 6mm ply ) M4 & M6 Screws. ( No & length to suit ) M6 Wing Nuts. ( approx. 6 of - depends on which version ) Foam insert. ( for cheaper alternate ) Hot Glue ... ( to secure / fix / seal components ) 3D Printed Parts : Hose Adaptor. ( to suit either A4/5/6 model ) Hose Insert / Connector. Notes : Exact number of nuts & bolts will depend on which model you decide to make - TBA ... The foam insert is a great time saver & works just as well ... I have re-used some 3D items found around here on Thingiverse ... The A6 hose connector can be found here : 'Remixed From' ... Also see 'links' section for other files ... Assembly Tools : Screwdriver ... ( + type depends on what screw used ) Counter Sink Bit ... Allen key ... ( if using Hex bolts ) Spanner ... Sharp knife ... Method : Get the frames / components cut-out to your preferred size / method ... Print out a hose mount / clamp as required for the model you are using ... Put all the frames together & check them to make sure the holes are aligned. ( You may need to re-drill them out depending on size of bolts used ) Collect / gather all the nuts & bolts required for assembly ... Counter sink all the relevant bits to suit flush mount screws or type of fixing you are using ... ( Use the images for a guide ) ... Depending on which way you prefer to have the bolts facing or type of fixing ... Dry assemble components starting with the back & work your way forward to the platen. When you are happy with final appearance, can fix it permanently with glue. The A5 version can use various types of inners & may need a slight trimming of top + bottom parts to fit the printed duct if used ... ( I found another work around is to cut thinner 3/4mm inner layers ) Once assembled, do a quick test run by applying suction to make sure it all works smoothly without any sticky points or loss of suction ... Go forth & multiply - as they say ... :) Enjoy, Bantum ... Notes : I've used some larger screws than necessary ... ( used what I had lying around ) I used a hot glue gun to secure parts together, mainly to stop them coming apart, washers falling out, etc. ... In use Operational Procedures : A few tips of how to use the machine ... Clear a space & get set up with your Former, Vacuum, Heat source & Tools ... Select your choice of plastic to place into platen & get ready to go. Can use a template to cut the plastic sheets to fit. + only need to tighten them screws up finger tight. ( Some types of plastic can be found in materials selection ) Make sure to your place mould centrally on former ... ( can add washers under to improve edges ) Place the loaded platen ready to heat up ... ( found if you lean it up against the base works best ) Take your heat source & gently heat up the plastic with it ( heat gun ) until its ready to go ... ( it should be soft enough to form with, but not too hot that it melts ) Turn on suction after you have smoothly located platen ... Wait till cooled - then turn of ... Remove from mould ... Materials Selection : Couple of pointers on the types of plastic that can be used in the vacuum former ... Polypropylene Polycarbonate Old Milk Bottles ( make sure to wash them ) ( more to be added ) Tools & Tips : A few other tools / tips I found to help in the process ... PPE - Gloves & Eye protection are a must ... Set up a hot gun / heating element as required ... A video of forming procedure can be found somewhere on here ... :) Make sure to push down on plastic edges while cooling to create crisp edges ... Helps to put 'locators' in mould to assist in joining halves later ... Notes Generally : The A4/A5 hose connector is designed to slot into the gap, it may need some sealant to make air tight ... ( Have found it does have a weak spot, so will need to be handled carefully ) For those who have already printed out their duct connector, an alternate fix is to print out the Duct Clamp & glue it to the existing connector ( images to come ) ... The larger A4 print files are preliminary, there may be errors / omissions in them ... :) Have also updated the A4 Hose connector STL file as it had to many errors in it ... :/ Added a template to enable cut-out of Milk cartons for forming on A5 Sheet ( More to come on this ) Found the A5 Hose Connector has a weak point, so have added a clamp with extra fixings ( may look at redesigning this later ) for stronger mounting. Looking to do a revised Layout for the A5, primarily to reduce waste + maximise cut time ... ( still need to check it ) Update : I have experimented with foam inserts to achieve a cost reduction ... :) ( will post up the drawings later ) Tips : Some of the holes in various locations may have wandered off alignment, or vary in size - so may need to check them beforehand ... :( Depending on which version you choose to make - be sure to get all the right parts together for assembly ... Edits Revised text & layout - Dec 2016. Revised CAD layout & added 'Hose Connector' - Dec 2016. Added a A4 Vacuum Former - Feb 2017 Revised A4 Drawing for laser cutting ... Added hose Connector ... Add some more images + Revised files ... Added A5 Vacuum Former - Mar 2017 Added a cut-out template for A5 sheets ... More images added ... Revised & added more info / files ... Added alternate A5 Layout ... Add fix for A5 Hose Duct ... Added a few 'in use' tips / applications ... May 2017 Add revised A5 Hose Connector - Rev B... Oct 2017 Add Rev C in A5 size + revise generally the page... Dec 2017 Add a draft version of assembly procedures ... Sept 2019 Links This is also a great counterpart to supplement the process :https://www.thingiverse.com/thing:2027135 The A6 hose connector can be found here :https://www.thingiverse.com/thing:25802

With this file you will be able to print A6 / A5 / A4 Vacuum Formers with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on A6 / A5 / A4 Vacuum Formers.