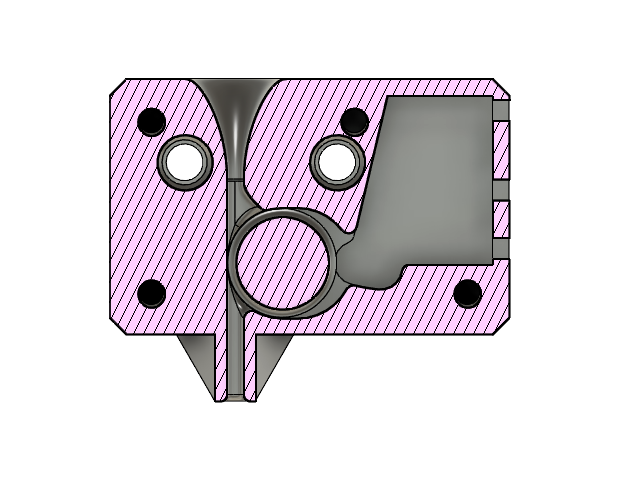

A8 Filament runout sensor & guide - direct mount

thingiverse

A simple filament guide with integrated micro swich as filament runout sensor. It is directly mounted on E-axis with the upper two M4 screws of X-axis bearing bushing. As the endstop swich has very small roller, I used grooved pulley (13 mm outer diameter, 2 mm groove) as interface part. If you have the original board, check out this video: https://youtu.be/UdETssS-ods?t=252 ...see 4:13 for the pin 27 location on 2004 LCD. In pins_ANET_10.h, comment with "//" #define SERVO0_PIN 27 (or maybe replace "27" with "-1" to steal the servo pin?) and define filament sensor pin here: #define FIL_RUNOUT_PIN 27 You can find my Marlin configurations in attached text file, tested with PLA->PETG->PLA->PETG filament switching when nozzle is very likely to clog, and works fine. V1.3 - part B with additional holes, so the M4 cylinder head hex screws can be tightened without opening the sensor, added some fancy embossing V1.2 - part A with larger openings M4 cylinder head hex screws, part B with slots for round head bolts M3, part C with hole 6 mm for improved weight and easy post-processing if necessary V1.1 - adjusted filament path shape, so the filament wouldn´t stuck during filament unload; enlarged holes for screws; other design optimisations to reduce weight and look less bulky Thanks to precise dimensions of the filemant guide from Cyberlamb, that I used so far, it was easy to find correct location of filament line to extruder. https://www.thingiverse.com/thing:2357589

With this file you will be able to print A8 Filament runout sensor & guide - direct mount with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on A8 Filament runout sensor & guide - direct mount.