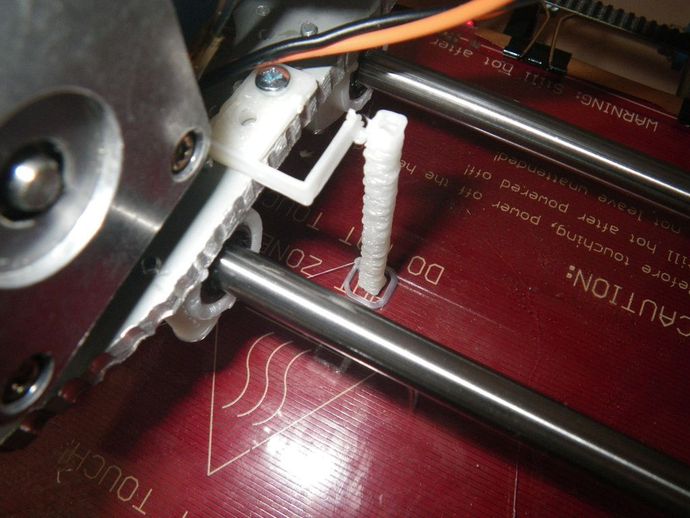

ABS force probe

thingiverse

To measure adhesion on a glass bed, create a small force probe and calibrate it using a milligram scale. Each 0.1mm step provides reproducible pressure increases. Achieve +/- 10% accuracy with repeated measurements. Use printer axes to move the probe and avoid softening due to heat. Test adhesion on glass bed coated with sugar/water/detergent mix, measuring 0.5-1N force at 55mm height. Further control of coating factors is required for better accuracy. ABS adhesion with ABS juice needs formal testing. For printing, adjust SCAD file to get correct wall thickness and use Slic3r or Skeinforge software. Some parts need to be cut off after printing as they are supports. Note that ABS probe may distort and relax, but readings are still repeatable. Visit http://forums.reprap.org/read.php?4,156005,216866#msg-216866 for more details.

With this file you will be able to print ABS force probe with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on ABS force probe.