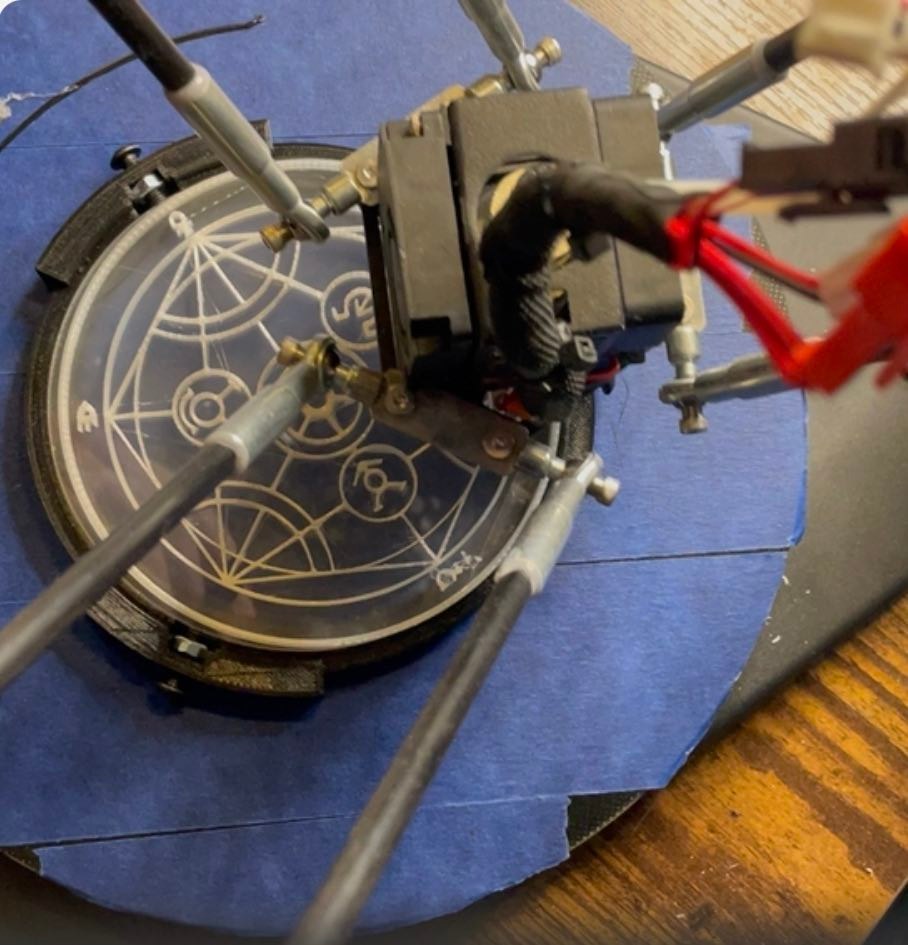

Acrylic Plate Vice

thingiverse

In place vice for printing on clear acrylic plates. I use this process to print designs then fill the space in-between with epoxy for use with LED's underneath. Mostly too make stands for different objects. I also used this method to print bearing couplings onto a plate for a rotating airbrush platform. It would have taken several hours to print the platform for the spinner vs an hour to print the coupling perfectly centered with no fasteners. This vice is for 4in acrylic plates. Though I attached a STEP file so you can edit and scale it for different shapes/sizes These are the exact ones that I use and are compatible- https://www.amazon.com/dp/B08PZ29L1T?psc=1&ref=ppx_yo2_dt_b_product_details The screws and nuts that I use are from Lowes, they must be at least 12mm Allen key M4 machine screws. Everything fits very tight at least on my printer. The best method I've found Is to thread the screw through the hole and into the nut then use that to pull into place. Some directions and tips - When printing the vice, make sure it is centered in cura then set your nozzle height a little to close to the build plate, I lower it .1mm past where the printer is working perfectly. Your goal is to get it stuck to the build plate. Also blue tape is very helpful for this and I highly suggest using it, both for adhesion and since its such a large circular part. Next you want to make sure you remove the clear sticker on the acrylic plates. It will fail if the plastic is still on. Adjust your printers layer height to the acrylic plate, It doesn't have to be perfect at least with PLA because it has very good adhesion. Its more important to keep it off of the acrylic so your nozzle doesn't melt the plate or clog up. Adhesion is good to the point where when pre heating your hot end, I would suggest keeping a piece of paper on top of the acrylic so any plastic falling out of the hot end doesn't drop and stick to the surface. Definitely make sure whatever design you are printing is perfectly centered on the build plate. For printing the vice I use .2mm layer height with 50% infill The wall that holds the plate has a 102mm diameter, I would suggest making the outside perimeter diameter of your design at most 101.8mm. Lastly when tightening the acrylic plate onto the vice tighten just enough, if you go to far the screw can cut into the acrylic, though this isn't usually an issue for me because most of mine get placed on a stand with LED's underneath. Good luck trying out this method! and if you have any questions you can leave a comment or message me on reddit u/StereochemistNJ

With this file you will be able to print Acrylic Plate Vice with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Acrylic Plate Vice.