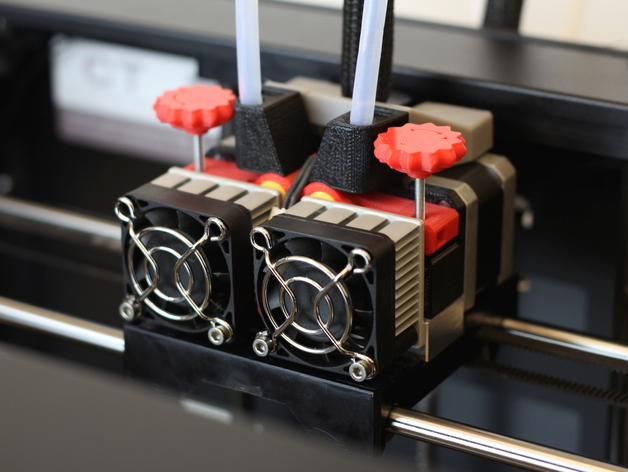

Adjustable Extruder Drive Block Upgrade for Replicator 2X

thingiverse

This adjustable extruder block design allows fine-tuning of pressure applied to the filament by the idler ball bearing, and is suitable for MakerBot Replicator 2X Desktop 3D printers. It's based on previous designs from Thingiverse (http://www.thingiverse.com/thing:136589 and http://www.thingiverse.com/thing:52203), but is not intended as a replacement for MakerBot's original extruder block. The adjustable design offers step-less filament grip pressure adjustment, a built-in filament dust filter with sponge, and a cover plate to protect stepper motor cables and connectors. All parts can be 3D printed in ABS plastic for optimal strength and heat resistance. The parts list includes 2 mm hex key, water pump pliers, beak pliers, and super glue. Detailed instructions are available at http://bit.ly/1eaYi3p or via the YouTube video at http://youtu.be/Z5md9XLeb-o. This design is a variation of current Adjustable Drive Block Upgrade for Replicator 2 and 1, which in turn is a variation of Spring-loaded Replicator 2 Drive Block, derived from three other previous designs. The MakerBot Replicator 2X Desktop 3D printer is best suited to 3D print models made of ABS plastic filament, which requires temperature-regulated and stable conditions. The adjustable extruder block features a lever left, lever right, base left, base right, bearing cover left, bearing cover right, and stepper motor cable cover, all 3D-printed parts. Fasteners and ball bearings can be reused from the original block. This is an experimental design, so use at your own risk. Learn from your experience using it.

With this file you will be able to print Adjustable Extruder Drive Block Upgrade for Replicator 2X with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Adjustable Extruder Drive Block Upgrade for Replicator 2X.