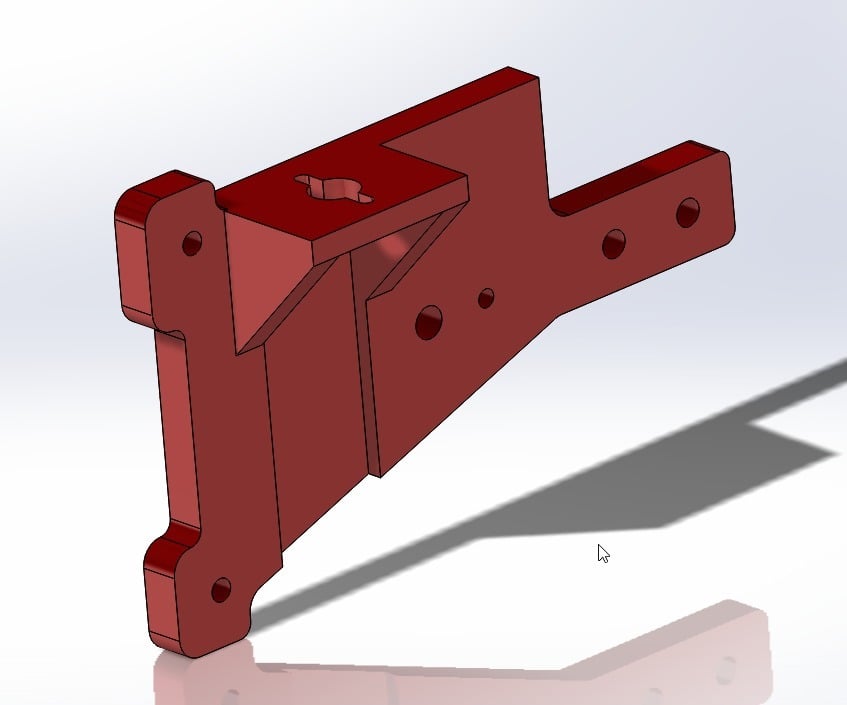

Alfawise U20 Dual Z Axis

thingiverse

La información proporcionada es una lista de componentes necesarios para la reparación o modificación de una impresora 3D Creality CR-10 Z, así como otros sistemas de impresión 3D. A continuación, se presentan los componentes mencionados junto con su descripción y el enlace a cada producto en AliExpress: 1. **Sistema de fijación superior de varilla roscada a vslot 2040**: Este componente es una herramienta para conectar la varilla roscada a un eje o mecanismo, específicamente al v-slot 2040. 2. **Sistema de acoplamiento flexible de varilla roscada 8mm a eje motor 5mm**: Este es un acoplamiento adaptable que permite una conexión flexible entre la varilla roscada y el eje del motor, lo que puede ser útil para mejorar la precisión y reducir la vibración en los sistemas mecánicos. 3. **Varilla (y Tuerca de latón) roscada de acero inoxidable de 4 flancos de inicio y 8mm de avance por rotación**: Esta es una varilla roscada de alta calidad, diseñada para uso en impresoras 3D y otros dispositivos mecánicos. Su material es acero inoxidable, lo que ofrece resistencia a la corrosión y durabilidad. 4. **Acoplamiento electrónico paralelo de 1 motor nema a 2 motores**: Este componente permite conectar un solo motor NEMA a dos motores separados, lo que puede ser útil en sistemas donde se requiere el control simultáneo de dos ejes o motores. 5. **Cable motor nema**: Este es un cable diseñado específicamente para la conexión de motores NEMA en impresoras 3D y otros dispositivos electrónicos. Su largo varía según las necesidades del usuario, pero se incluyen longitudes de 1 metro y 2 metros. **ADVERTENCIA IMPORTANTE:** Antes de conectar cualquier componente electrónico o mecánico a la placa madre de la impresora, es crucial verificar con un polímetro que las salidas de la conexión de motores Z son iguales en ambos motores. Si no se hace esta verificación, existe el riesgo de dañar la placa madre.

With this file you will be able to print Alfawise U20 Dual Z Axis with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Alfawise U20 Dual Z Axis.