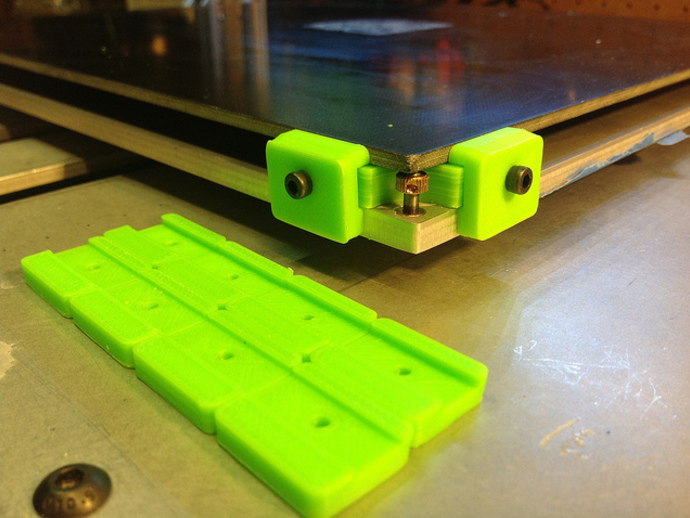

Aluminatus Corner Clamps

thingiverse

These corner brackets won't allow your build plate to slide around. Or become unlevel once the clamps are tightened. 8x M3x0.5-16lg screws and hex nuts are needed to complete a full set of corners. Corner parts: Corner_brkt_v3 - Used when you have ThorLabs Fine Adjustment Screws installed. Corner_brkt_v4 - Used with leveling shims, or use provision for installing an M3 set screw in the hole nearest the corner. Clip Parts: F-300, A-300, F-305, A-305. The F parts are intended to be fastened and act as stops. put them on the back edge and one side of the build surface. The A Parts have clearance that allows them to adjust to the edge of the build surface, and go on the sides opposite the F parts. 300 and 305 go with either 300 mm or 305 mm square build plates respectively. When tightening the A parts, only finger tight is needed. Two fingers on the shaft of the hex key is enough. Too tight can cause the build plate to bow. Even with finger tight, it can be necessary to loosen the screws to be able to remove the build plate. Misc: The text on the face of the A & F parts may not be really legible in the finished part. It depends on how much the first layer is squashed. If you need to deal with a build plate that isn't quite square. 1) Install A parts in place of F as needed. 2) Add shims between F parts and corner parts. (My personal preference) 3) Get the step files and mod them as needed.

With this file you will be able to print Aluminatus Corner Clamps with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Aluminatus Corner Clamps.