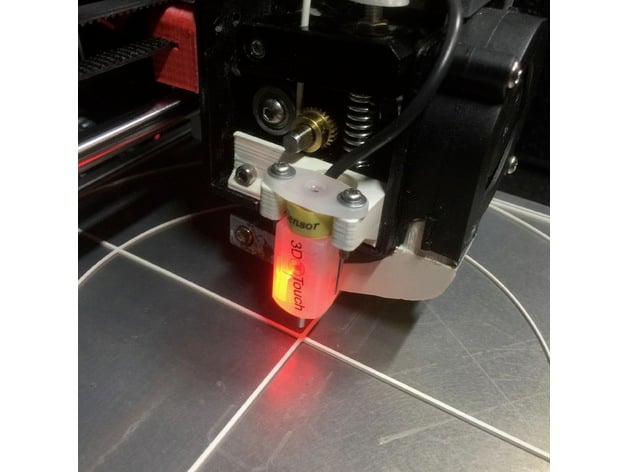

Anet A8 3D-Touch Mount

thingiverse

This is a mount for the Geeetech 3D-Touch / BLTouch Sensor for Anet A8 printers. This design is meant for people who do not use an extruder cooling fan and heatsink. (Both are not really needed as shown by multiple experiments of different users. Please no discussions about that.) I included the Fusion 360 file which makes it easy to modify if needed. The mount fits right onto the side of the extruder using the original (shorter) screws. It has little holes for the nuts of the sensor screws to make assembling easy. After assembling the sensor is very stiff connected to the j-frame. It will hardly move or bend on usage. I printed it topside down to get best stiffness. The model was adjusted to print without supports. I used the following print settings: Printer: Anet A8 Rafts: No Supports: No Resolution: 0.2 Infill: 30% You can find more information on Marlin and auto levelling at http://marlinfw.org/docs/configuration/configuration.html. The BL Touch sensor is available at https://www.indiegogo.com/projects/bltouch-auto-bed-leveling-sensor-for-3d-printers. The 3D-Touch sensor is available at http://www.geeetech.com/wiki/index.php/3DTouch_Auto_Leveling_Sensor. SkyNet3D download: https://www.facebook.com/skynet3ddevelopment/?fref=ts Anet A8 Marlin port sources: https://github.com/SkyNet3D/Marlin "Just Blinking" ? Read this: http://www.geeetech.com/forum/viewtopic.php?f=27&t=18263. Thanks to "Tobi As" for the wiring overview image!

With this file you will be able to print Anet A8 3D-Touch Mount with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Anet A8 3D-Touch Mount.