Anet E10 Marlin 2.0 Mks Sbase V1.3

thingiverse

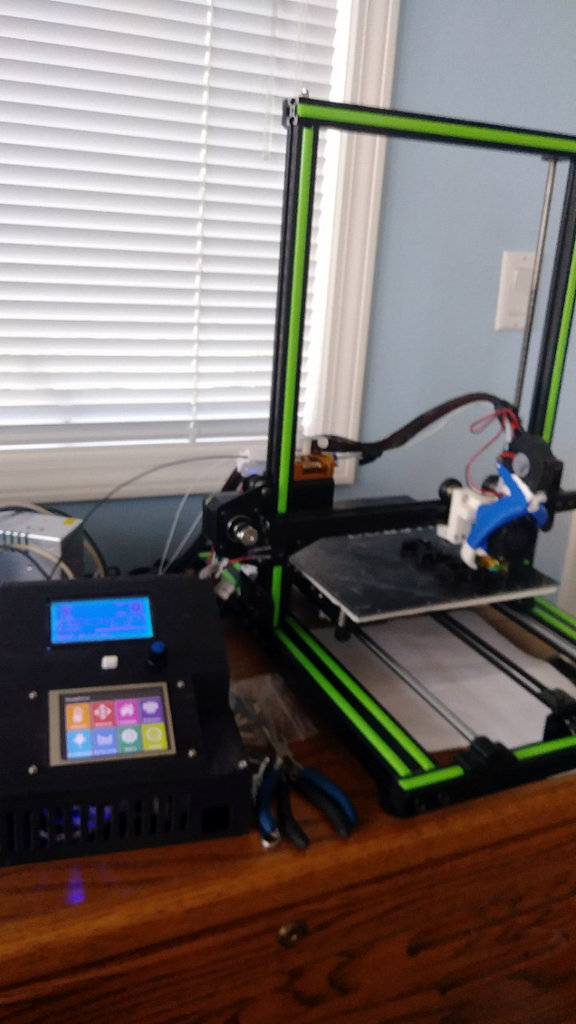

I bought this Anet E10 about a year ago, and have had many problems with it. I really wish I would have spent the extra money on a better machine to start out, but it seems that finally this machine is making fairly good prints at about 70mm/s. I now have many mods and 3d printed parts on my unit, and have replaced the Anet control board with a MKS SBase V1.3 board. I also did the 'Fast Decay' mod on the MKS board to improve print quality. I'll list my problems, solutions, and suggestions here if it might help anyone else. I'll also attach my Marlin Config files. Anet E10 Problems, out of the box: 1) Very hard time getting a good first layer, could not level the bed so that all four corners were good at any one time. -- Problem, found that my bed was not flat, and that both of my 8mm guide rods were bent. -- Solution, replaced guide rods, tried to re-flatten the bed as good as I could get it, and changed firmware to Marlin 1.x and enabled bed leveling using BLTouch. (Still using the Anet controller at this point) 2) Hot bed intermittent heating problems. (This appeared about a month after starting to use the machine) -- Problem. Anet only using one set of the pins on the bed connector, causing the connector to melt. -- Solution, My connector was already bad from too much heat, I soldered 12 AWG solid wire to the bed, and connect the heater now with a RC connector XT60. 3) Bad (intermittent bad) layer adhesion, no matter what temperature I printed at. You could see color changes within the layers. -- Problem. Anet did a terrible job connecting the hot end heater element. -- Solution, removed all the insulation and heat shrink, found both connections were crimped mostly onto the wire insulation. Replaced heating element with new unit that has long enough wires to run back to the controller. 4) Was getting diagonal lines within the print. -- Problem, a bad bearing in one of the X carriage wheels. -- Solution, replaced bad wheels on X carriage. 5) Had bad bearing noise on fast Y axis moves. -- Problem, bad bearings in Y axis bearing blocks, possibly due to the bent 8mm guide rods. -- Solution, right now, I'm using a 3D printed bearing, seems to be fine, I believe it is this one: https://www.thingiverse.com/thing:2537701 6) Z axis gets out of alignment on nearly every print. -- Problem, The left side Z axis motor has both the X Axis stepper, and the Extruder stepper on it. So when the motors are off the left side drifts down. -- Solution, (Now using Marlin 2) Marlin 2 now has the option to do a auto Z alignment! The G34 command in configuration_adv.h #define Z_STEPPER_AUTO_ALIGN Saving me from having to manually check the Z height on each side before each print. (Hats off to the Marlin crew!, really some good stuff in Marlin 2) also, set this in configuration_adv.h (for MKS SBase V1.3 board): define MINIMUM_STEPPER_PULSE 4 // Was 2 Marlin 2.0 Features I'm now using on the MKS SBase Board: -- Auto Bed Leveling with a capacitive probe -- Auto Z axis Alignment -- Filament runout sensor -- Dual Displays, 1 RepRap Generic 128x64 LCD, and one color touch 3.2" screen -- Backlash compensation -- JUNCTION_DEVIATION instead of Jerk Controls set at 0.04 -- Linear Advance for Extrusion, once dialed in, it made my prints much nicer (at 0.9 for me) -- Filament change controls to change filament colors mid print with M600

With this file you will be able to print Anet E10 Marlin 2.0 Mks Sbase V1.3 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Anet E10 Marlin 2.0 Mks Sbase V1.3.