Antique Fractal Vise Replica

thingiverse

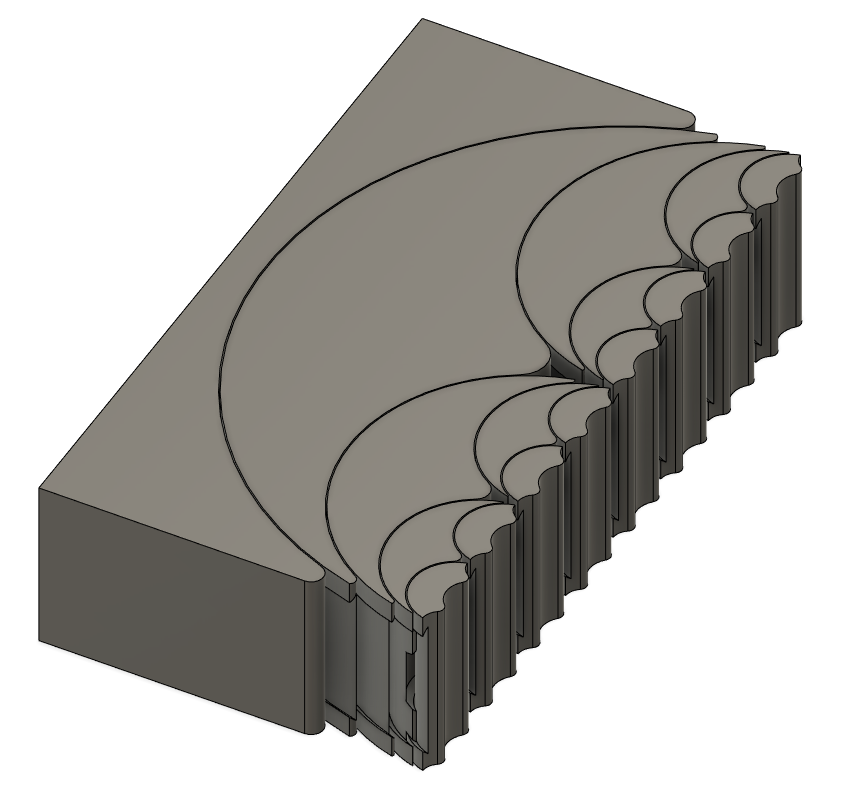

UPDATE: 0.2mm of clearance added to the radius of each jaw to address assembly issues, I was planning on sanding in this clearance myself when I get a chance to print it but thinking about it more it really does just make sense to print it as such. Please let me know if anyone else gets printing issues going forward with this! Redownloading may help. I was inspired by the video Hand Tool Rescue posted today on an antique fractal vise design first patented in 1912, US1059545A. This is intended to fit into a large machine vise, but even a conventional bench vise may work as long as the travel is long enough and the jaws can be attached securely. I just put together this first version in a couple of hours using Fusion 360 and I won't have access to my printer until the end of the summer so please let me know if you're able to print it successfully or have any suggestions! Design Details: Each rotating jaw is dovetailed together with 0.2mm of clearance and is able to rotate up to 30 degrees without interference, as shown in the second and third pictures. The total assembly height is 25mm and width is 100.6mm. A pair of complete jaw assemblies touching against each other would have a total length of 110mm. Flat and grooved versions of the vise mount are provided, I would guess that the flat version would work best in a machine vise whereas the grooved may work if it is held in place on the jaws of a conventional bench vise (magnets work great for attaching wooden/plastic soft jaws so that may be a good course of action) Bill of materials (per jaw assembly): 1x Vise Mount (flat or grooved) 1x Jaw A 2x Jaw B 4x Jaw C 8x Jaw D Printing: I would recommend printing each and every part separately, the assembly is included just for reference since printing in place would almost certainly fuse all of the jaws together. A very well-calibrated printer with tight belts must be used to ensure accurate form, and each part should be printed vertically facing the same way (as they would be arranged in the assembly) to ensure dimensional differences between axes don't throw things off. Printing one Jaw D and one Jaw C would likely be enough to see if the fit is satisfactory before printing the rest of the assembly. Support material would be necessary but only for the dovetail. Parts can then be carefully cleaned and sanded/filed to fit. The jaws do not lock into the slots at this time as I wanted to keep the design simple.

With this file you will be able to print Antique Fractal Vise Replica with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Antique Fractal Vise Replica.