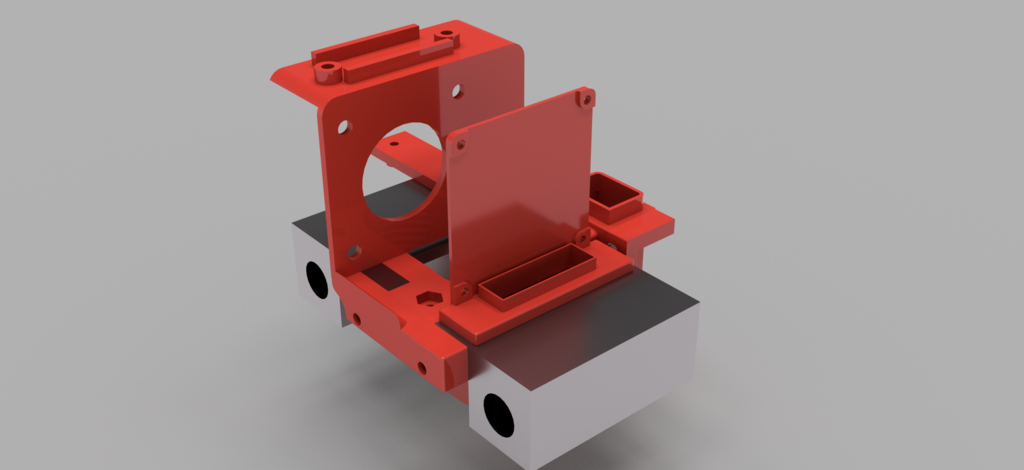

Anycubic 4Max Pro E3D V6 / Volcano with Titan extruder, adjustable height hotend duct

thingiverse

Added pictures of the installed version on my 4Max Pro. Also i am using a new fan duct design, blowing from two sides. If you use The new design, make sure to set your part-cooling fan speed to 20% less than with the old one. Turned out, that the new duct must be printed with a temparature stable material. Bed temps above 60 will make the duct in PLA or even PLA+ unstable. I am using a resin printed version and have no problems with it even on higher temps. UPDATED VERSION is here: Please enjoy the final version of the design. The previous fan duct for the cooling of the sink was replaced with a small 40x40 radial fan. Motor mount plate was optimized to hold electronics and fit with cable chain. Printed the following materials without any issues (see example pictures): - PLA - PLA+ - PETG - TPU - ABS - Nylon - Wood Additional info: • I added a BuildTak magnetic plate onto the glass plate of the 4Max Pro and sprayed the flex plate with stick spray. This was a perfect solution for all materials, even nylon. It sticked perfectly to the plate and was easy to remove due to bending of the plate • I used a retraction of 0.75 @ 50 mm/s wich turned to fit for most materials (even nylon but not for TPU) Due to the fact, that there is no adequat design to use a standard E3D V6 or Volcano hotend with a E3D Titan extruder on my 4Max Pro, i started out to design my own thing :-) Originally i wanted to install a E3D Hemera with a Volcano hotend but it is not available currently and i had a V6 and a Titan laying around :-). So why not give it a try... It is based on the aluminium x carriage used on the CTC Flashforge Makerbot (links see on end of summary). Since the carriage is way smaller than the one used on the original 4Max Pro, there were quite some challenges to solve. The hotend fan is a simple design to fit but is adjustable in mount height so it will fit on various hotends. The design consists of 4 parts: - the base mount plate for the carriage, which also includes the duct for the sink cooling - the adjustable hotend duct/fan - the motor mount to fix the motor and extruder to the carriage and hold the electronic board (and additionally a mount for my cable chain) - the changed longer endstop mount You would need the additional material as following: - some M3 screws, washers and nuts - HAWKUNG Turbo Fan 4010 40x40x10 DC 12V - SUNON MF50151VX-A99 DC 12V - E3D V6 Hotend (or Volcano) - E3D Titan Extruder (preferrable with E3D compact but powerful motor) - CTC Flashforge Makerbox Aluminium X Carriage - MISUMI LMUW8 (previously LM8LUU) bearings (the ones in the carriage were crappy) Since the design is quite press fit into the carriage, i printed the sink fan mount plate and the hotend duct using my Photon S with Anycubic Black. Also the sink cooling duct is difficile for a FDM printer, but you might try. Print parameters where 0.05 layer height, 8s, 3 initial layers @ 50 s. Motor mount plate and endstop sensor mount can be printed FDM. I also added the allready supported files (Chitubox projects), ready for print which turned out to be nearly perfect on my Photon S. But it is not neccessary to have a 100% perfect print since you can sand the parts for fitting. If you oil the final resin parts (after sanding and cleaning) they will be looking nicely. Instructions: 1. Unmount the 4Max Pro standard hotend (see various instructions on thingiverse, for example the Hemera conversion by Alfrank) 2. Mount aluminum carriage (including Misumi bearings, check belt tension) 3. Print all parts and test for fitting (maybe sand or post process as you want to) 4. Assemble the V6 hotend 5. Assemble the Titan extruder (with the motor mount plate between motor and extruder) but skip the lid 6. Mount the HAWKUNG fan (with short M2 screws and nuts) 7. Put the hotend into the base plate (from below) and assemble with the Titan extruder 8. Screw on the Titans lid and make sure everything fits properly 9. Add M3 nuts into base mount plate and motor mount plate 10. Add base plate into carriage and screw with 2 M3 screws from below into the inserted nuts in the base plate and the motor plate foot. Check that the left M3 screw is not too long so it will not lift the titan when assembling 11. Mount the radial fan to the hotend cooler. Fit with a M3 screw and nut into mount point 12. Mount the hotend cooler to the carriage and adjust height (use washers) 13. Mount the electronic board to the motor plate 14. OPTIONAL when using E3D motor: check wiring for fitting the E3D motor 15. Use Anycubic heater from old hotend and E3D thermistor supplied with V6 (cut properly and add a connector for electronic board) 16. Connect heater, thermistor, radial fan and sink fan to board 17. Mount new endstop holder and adjust with your hotend 18. Reattach ribbon cable, cleanup installation 19. Modify firmware for a. new thermistor type (5) b. max temperature set to 300° for mine (which enabled me to print with 285°) c. new bed offset (stock was -8, mine was -13 for X) d. invert motor direction when using E3D motor for E0 e. adjust E-Steps for E3D motor (mine was 812) 20. Relevel bed 21. Have fun printing The Titan is not the "top-of-the-line" extruder since it is not a dual gear extruder, but using a full-metal implementation will give you speed and better printing results on all materials. Even with flexible ones (reduced print speed) it works fine. The design is customizable to adopt a BMG extruder. Feel free to use and remix. Please post makes and submit optimizations to me so i can add them to the current design. Things that might need optimization: • wiring and/or wire mount holes for cable tie • part cooling fan (current one is only one sided, at least 2 directions would improve quality) Greets 2 the community Links to materials: X Carriage: https://bit.ly/2AjQdAx SUNON Radial Fan: https://amzn.to/2ZWQnJh HAWKUNG Turbo Fan 4010 40x40x10 DC 12V: https://amzn.to/2AGDzft Misumi Bearings: https://amzn.to/2yEITiA Used resins: Anycubic Black Used filaments: SUNLU PETG Black for motor mount plate

With this file you will be able to print Anycubic 4Max Pro E3D V6 / Volcano with Titan extruder, adjustable height hotend duct with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Anycubic 4Max Pro E3D V6 / Volcano with Titan extruder, adjustable height hotend duct.