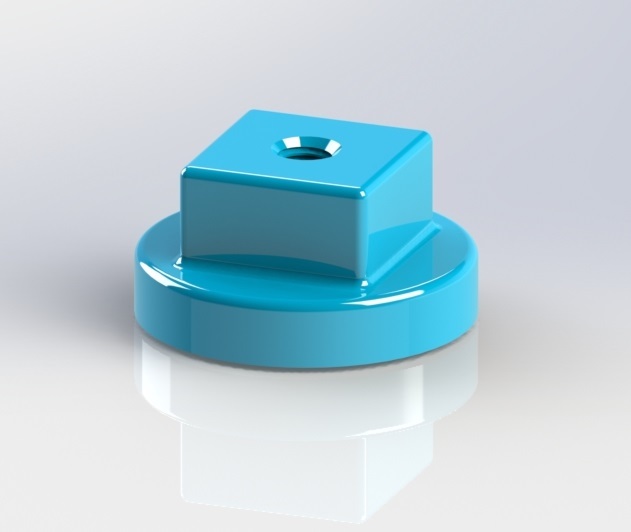

Anycubic I3 Mega S Z Stop Problem Solution

thingiverse

Anycubic I3 Mega S Z Stop uses a 2.5mm locknut to interact with z stop micro switch. The lack of a sufficient planer surface to interact with micro switch actuation lever causes extreme variation in Z homing resulting in damage to a great work bed surface. This simple solution solves the problem. I have supplied 2 configurations of varying tightness in threads. Although the 100 will more easily start to thread onto the screw, forcing the 90 to thread onto the screw will result in a nice tight fit not requiring a lock nut to keep it from accidently turning. Any version used should be pre fitted to the screw out of the machine preferably with a power driver to improve the printed threads. Use the supplied lock nut for adjusting the spring and use the supplied spring tension nut as a lock nut against the printed Z Stop Nut if at all. Cheers! Note: WaGi-3D Has a nice insert to secure the top of the Z Stop Screw and keep it from wobbling. I just downloaded it myself and will be using it as it also addresses part of the cause of this problem. I would estimate my part is a 99% solution and with the addition of his part well, "Damn!" Here's the link to his part https://www.thingiverse.com/thing:3534757/files

With this file you will be able to print Anycubic I3 Mega S Z Stop Problem Solution with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Anycubic I3 Mega S Z Stop Problem Solution.