AnyCubic Predator Filament Sensor Feed

thingiverse

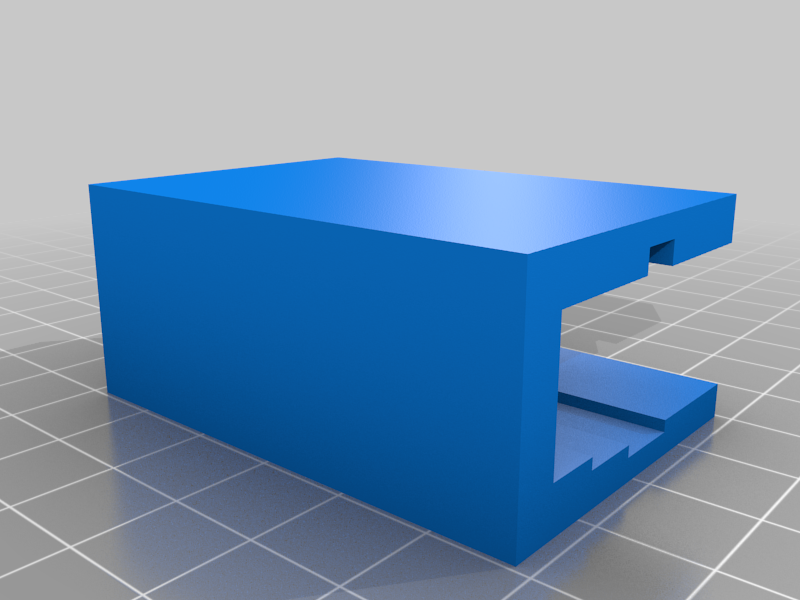

I had planned to do my sensor repositioning a long time ago but I never got around to it. A particularly brittle roll of filament made me think that now was the right time, considering how difficult it was to feed the extruder with the filament sensor in the way. There are several designs that help with the relocation of the filament sensor from the original location to inside the top of the printer. Most designs provide a top casing that allows feeding the filament into the sensor from the top while the top cover is in place. These usually use the existing bowden connector to feed the filament through the top metal plate and requires the outlet of the filament sensor to be pushed down onto the connector. The basic procedure for repositioning the sensor is to unscrew the filament sensor from the top plate, remove the wire connector and remount it on the reverse side of the top plate. The wire for the sensor needs to be moved back up into the top section so it can be reconnected to the sensor. This procedure is quite easy to do. I tried a couple of the other designs but was not happy with the fit and I found that the sensor sitting on the bowden connector was too tight. I ended up removing the bowden connector all together and inserted a small plastic "tweezers" cover with the end cut off instead. Basically a small plastic funnel. This worked fine but I decided that a custom printable part would be better, especially if you didn't happen to have these other parts lying around. Since I was going to be designing a part for that I decided to try my hand at designing the upper part as well. I designed the bottom filament sensor guide to sit over the 12mm raised ring before the mounting bracket is put in place. The mounting bracket and sensor are then tightened down. The filament should fit easily through the sensor and through the bottom guide. With the sensor securely fastened, the top filament sensor casing is then slid down over the filament sensor. It should sit down so the top of the casing is a couple millimetres below the cover. If desired, a small piece of bowden tube can be inserted so it sticks out of the top of the cover, but it is not really necessary. Filament should slide easily through the upper casing, through the filament sensor and out, through the top plate. Note: my white filament ran out so I finished the print in blue. I also added a trimmed top casing version. I removed some excess material but I have not printed and tried this version yet. It should fit the same as the original.

With this file you will be able to print AnyCubic Predator Filament Sensor Feed with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on AnyCubic Predator Filament Sensor Feed.