Automatic Tire Inflation System

thingiverse

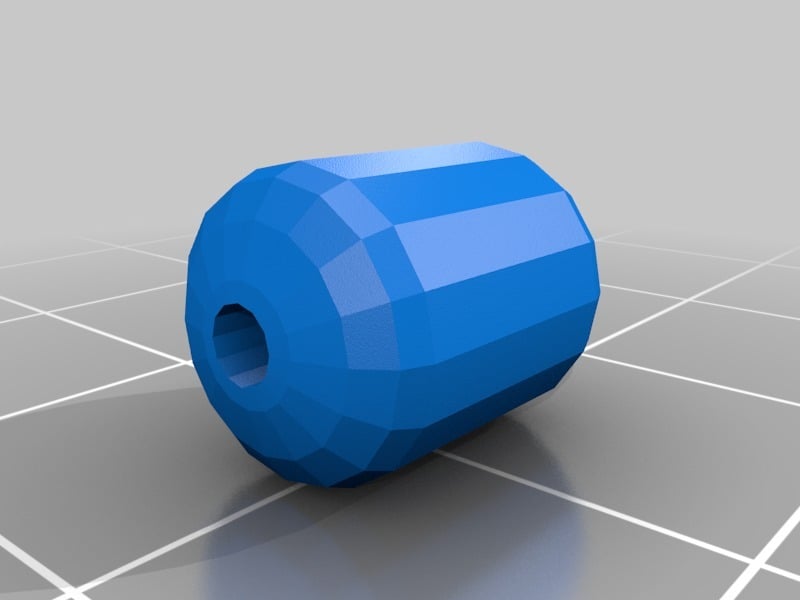

Tire pressure is a crucial safety factor, measuring the amount of air in a vehicle's tires in pounds per square inch. Drivers must ensure their tires are properly inflated to avoid accidents and other issues. Unfortunately, many people neglect to check their tire pressure regularly. According to a National Highway Traffic Safety Administration (NHTSA) survey conducted in February 2001, only 29% of respondents checked their tire pressure at least once a month. As a result, approximately 80% of vehicles on the road are driving with one or more under-inflated tires. Under-inflation can lead to numerous problems, including wasted fuel (an estimated 1.2 billion gallons annually) and increased accident risk (vehicles with under-inflated tires are three times more likely to be involved in a crash). While there may not be direct legal consequences for neglecting tire pressure, improper inflation can compromise vehicle performance, safety, and comfort. The proposed system aims to alleviate these issues by implementing automatic monitoring and maintenance of recommended tire pressure. This design goes beyond the minimum requirements set by the Transportation Recall Enhancement, Accountability, and Documentation (TREAD) Act of 2000, which mandates that new vehicles indicate when a tire is significantly under-inflated. The proposed system consists of several key components, including: A. Operator Control Manual: Allows drivers to select from pre-saved tire pressure levels for optimal performance in various driving conditions. B. Electronic Control Unit (ECU): Sends signals to the Pneumatic Control Unit (PCU) to determine air pressure levels and instruct it to adjust them accordingly. C. Pneumatic Control Unit (PCU): Works with the air compressor to deliver or remove compressed air from tires as needed. D. Air Compressor: Provides a supply of compressed air, which is stored in a 3D-printed storage tank. E. Pipes or Tubes: Transport compressed air from the air source to the tires. F. Check Valves: Ensure that each tire maintains its recommended air pressure level independently. The system's design includes a scaled model of the air storage tank, which can hold up to 2 gallons of compressed air. This is sufficient for maintaining optimal tire pressure levels within 5% of the recommended range, with an estimated maximum loss of 0.45 gallons in a single tire before the system kicks in. The proposed system also includes models of the check-valves used to maintain individual tire pressures. Four check-valves are required for a standard passenger vehicle, and they have been designed to operate efficiently while maintaining optimal air pressure levels.

With this file you will be able to print Automatic Tire Inflation System with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Automatic Tire Inflation System.