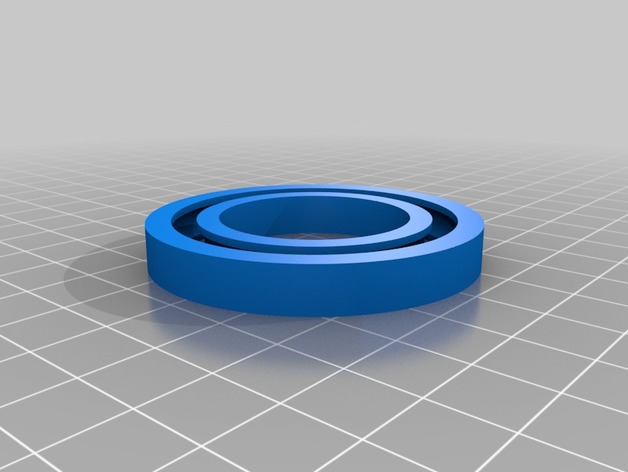

Bearing using Airsoft Pellets (Parametric)

thingiverse

Simple bearing using 6mm airsoft pellets as balls/rollers. Designed in Autodesk Fusion 360. The .stl file is set up for a 31mm shaft and a 54mm outside diameter, which works well on my Monoprice MakerSelect (v1) printer and a roll of Hatchbox PLA. This is not scalable - use the parametric (.f3d) file for a bearing with different inner or outer diameter (or different ball size). The clearance on this is fairly tight. The first few pellets insert easily, but eventually you reach a point where you have to really force them in. I used the flat side of a paint scraper to provide a little extra surface area to push on and was able to get all of the balls inserted. The .f3d file is included - use Fusion 360 to modify the parameters to suit your own needs. Future improvements: Add width parameter to control overall width of bearing. Chamfer or fillet inner and outer races. Add retainer to help with larger diameter balls. Customize to better suit 3D printing Hatchbox spools. Printer: Monoprice MakerSelect (v1) Rafts: No Supports: No Resolution: .16 Layer Infill: 40% Post-Printing Assembly For the STL file, you will need 22 6mm airsoft pellets. Place the smaller ring inside the larger, then begin inserting airsoft pellets between the races. You need to put as many pellets as will fill the space between the races. Inserting the last few (half?) of the pellets will take some force. Use a larger flat object (I used the flat side of a paint scraper) to push the balls into the space between the races. Some lubrication (silicone spray works well) to quiet the bearing and allow it to roll more smoothly.

With this file you will be able to print Bearing using Airsoft Pellets (Parametric) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Bearing using Airsoft Pellets (Parametric).