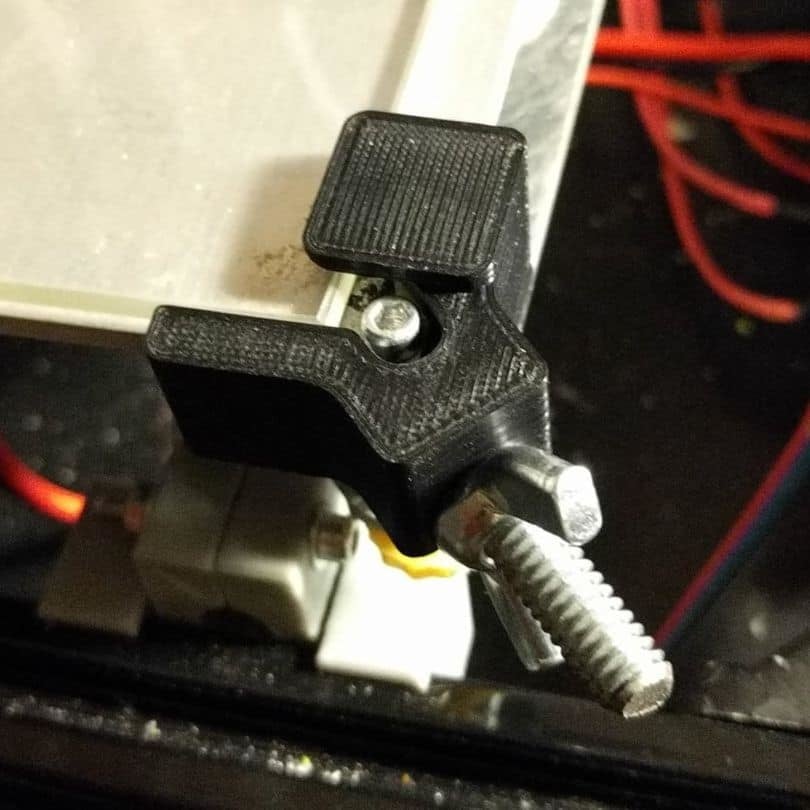

Bed clamps for glass print plate

thingiverse

I looked at several different clamping mechanisms as an alternative to using binder clips. The binder clips took up too much room and would occasionally get hit by the print head on larger jobs. I couldn't find ones that worked with the glass I was using, so I took some ideas from others and made my own. I was quite inspired by this one in particular so special thanks to https://www.thingiverse.com/runswithscissors95/about and his thing https://www.thingiverse.com/thing:2313925 I tried to use the knurled knob and the threaded stud from the above "thing", but found they were not strong enough to get a good hold of the glass. The threaded bolt kept breaking. Instead, I made my own threaded parts out of 1/4-20 bolts and cut their heads off. I made a hole jig out of an old long nut I had around (pictured). This way I could make sure the holes were consistent between the studs and the bit wouldn't slip off when drilling. The studs should be about 40mm long. The cross holes are drilled to 1/8" to allow the 3mm bed height adjustment screws to pass through. The installation process is a little hairy because you have to have the printed clip, the 3mm bolt, the 3mm nut and the stud all installed at the same time. The 3mm bolt passes through the clip top, through the stud hole, then the 3mm nut put on. I suggest doing this on all four corners first. Then put the springs on, then pass the 3mm bolts down through the Y carriage mount. A picture is included here that shows the first step assembly with the Y carriage portion cut away so you can see the nut (yellow) in place. The glass this is designed for measures 213x200x3mm. I bought mine on Amazon here: https://www.amazon.ca/gp/product/B015R1UOKW/ref=oh_aui_detailpage_o02_s00?ie=UTF8&psc=1 I printed this with full supports because it needs to be accurate and any bridging would make it not fit quite right. It's a little work in post processing to get the supports out, but it's kind of needed. I printed this in ABS because I print a lot in ABS and therefore print at higher bed temps (90 degrees). I think that doing this in PLA will not be good as it would soften too much with a heated bed and allow the glass to shift in a job. Not sure about PETG. The clamp1.stl and clamp2.stl are mirrors of each other so make sure to print two of each. Refer to the photo above for how to install the clamps oriented to each other.

With this file you will be able to print Bed clamps for glass print plate with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Bed clamps for glass print plate.