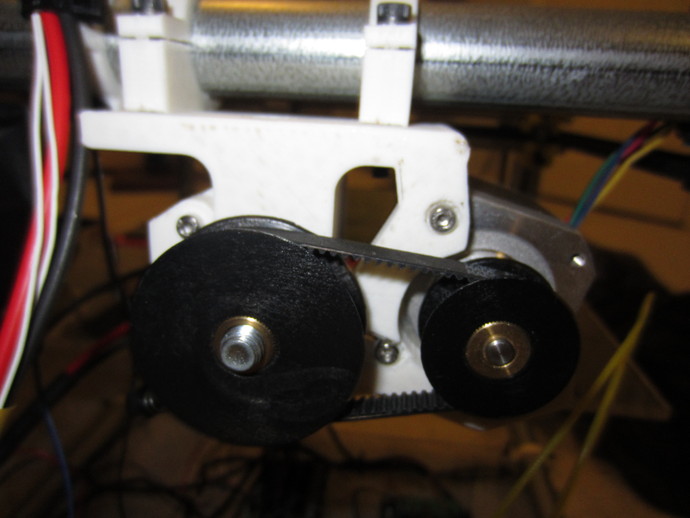

Belt Drive Wade's Extruder

thingiverse

Why? Cuz it's retro! Hipsters like Bre will show up at your door just to tell you how cool your extruder is. Actually, belt drive has several advantages over printed gearing. gears don't wear out backlash-free smoother operation easier to tightly clamp gt2 pulleys onto the motor shaft less friction This mod changes the motor mount to accommodate belt tensioning and includes a motor-side bearing brace. Mounted on UConduit (shown). I'll be making one for my MendelMax and posting pictures soon. Instructions Required parts: GT2 pulley - 5mm bore (17T standard, 36T bowden) GT2 pulley - 8mm bore (65T standard, 60T bowden) GT2 belt (88T standard, 94T bowden)* 608 bearings (I used 3x total, including the one for the wade's idler to properly space the hobbing, this could be different for you depending on where the hob is on your bolt) M4x50 screws for clamping the M4 wade's idler standard wade's hardware 4mm x 1/8 NPT push-to-connect (bowden only) I have only tested the bowden configuration so far (on my UConduit h-bot http://www.thingiverse.com/thing:102972), so this is a "work in progress" for another week or so. I will be testing the non-bowden configuration soon... although I don't anticipate any problems. I sourced belts and pulleys from http://store.terawattindustries.com/77-00str00der-belt-driven-extruder.html#/00str00der_assembly_options-belt_and_gears_only/00str00der_parts_options-no_nema17_motor

With this file you will be able to print Belt Drive Wade's Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Belt Drive Wade's Extruder.