Belt-Driven NEMA 17 Linear Motion System

thingiverse

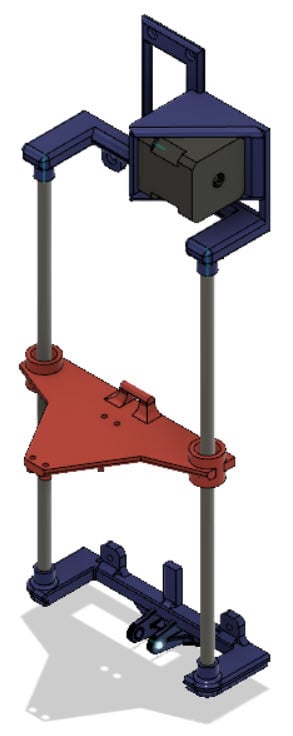

These files support linear motion using 8mm rods, an idler, and a NEMA 17 stepper motor. It was originally designed for vertical motion in Senior Design 1 at Clemson University for a Towers of Hanoi project. Additional Hardware Needed - NEMA 17 Stepper Motor [Amazon](https://www.amazon.com/STEPPERONLINE-Stepper-Bipolar-Connector-compatible/dp/B00PNEQKC0/ref=sr_1_5) - Linear Bearings - I used solid polymer bearings. [Amazon](https://www.amazon.com/Printer-Solid-Polymer-LM8UU-Bearing/dp/B06XPRCMJS/ref=sr_1_10) - GT2 timing belt and idlers - just get a set. [Amazon](https://www.amazon.com/KeeYees-Timing-Tensioner-Torsion-Printer/dp/B07JKT5BZQ/ref=sr_1_4?crid=3S4QP0TCVPNUO&keywords=gt2+timing+belt&qid=1582209565&s=industrial&sprefix=gt2+%2Cindustrial%2C160&sr=1-4) - 4 M3 bolts, 1 M4 bolt (~25mm), 1 M4 nut - 8mm linear rod of desired length Assembly Instructions As shown in the image, you print one of each file. Connect the NEMA 17 stepper motor to the top piece using 3mm bolts, then attach a geared tooth pulley to it. The bottom piece supports an idler attached using a 4mm bolt. Attach a GT2 belt to the top of the SlidingPiece using zip ties - loop the belt around the pole in the middle in a way that the pulley teeth interlock with each other, then use a few zip ties to attach it together. Run the timing belt up and around the toothed pulley on the stepper motor, then around the idler, then attach it to the other side of the sliding piece. Notes and tips I designed this to work with approximately 11" long linear rods, but it should work with any length. The only issues you might run into are the timing belt hitting the plastic parts or itself - you can edit the files in Fusion 360 to add more offset. The top and bottom parts should print without supports just fine. My sliding plate has some small offsets for our gripper, but if you don't need them then just delete them. Bonus files Gripper: Our project involved gripping rings of variable size from 2" up to 5.5", so we found/printed a parametric gripper. The "Gripper V4.zip" file is my SCAD file modified to fit up to 5.5" objects, while being driven by a standard cheap servo motor. [Original Thingiverse link](https://www.thingiverse.com/thing:27468)

With this file you will be able to print Belt-Driven NEMA 17 Linear Motion System with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Belt-Driven NEMA 17 Linear Motion System.