Belted extruder gears for Greg's Wade / L3K and many more

thingiverse

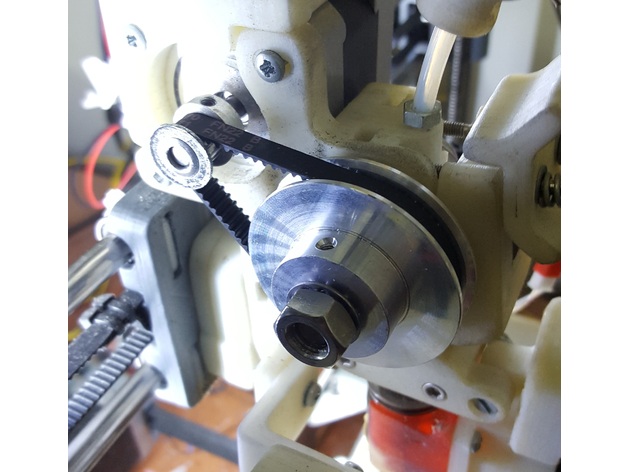

UPDATE (06-FEB-2017): After a year of flawless work with the ABS Crown pulley I had some aluminum pulleys around and ended using an aluminum standard GT2/60T pulley with a GT2/16T pulley. Added a model for a manual handler fixed to the pulley with M3 screws. Torque of 1:3.75. 580 Steps for 16 microstepping pololus and standard 8mm hobbed bolt. No so cheap but more durable/precise. Used high torque 160mm S2M belts. Don't know why, but extrusion seems to be smoother now. I'll update this when I have more info. Caution with your version/lenght of the hobbed bolt due to the 60T pulley's extra height. I have attached it to the bolt threads with m3 showt screws, and the handler with regular M3 screws. Used an M3 nut with anti slip to fix even more the pulley but that's not required. Printed the handler in black ABS as after a year working with the plastic pulley it's not any more as pretty white as in the original pics show here heheh, so I opted for a more discrete black handler, you know... UPDATE: (23-APR-2016): Posted sources as requested. Not a clean code anyway, sorry. UPDATE: (29-SEP-2015) Bunch of new models for cool style gears. Choose yours!!! Why enigma has an 'O'??? Why the "crown" model is so cool??? This is a GT2 gear I made with this excelent generator: http://www.thingiverse.com/thing:994807. I made some modifications to the original design just to make it fit in a L3K extruder with GT2 pulleys and a 6mm 200mm 100T GT2 belt. As I was previously using typical wade's 47T/9T herringbone gears, this also fits on ANY extruder using that gears without changes. I know there are quite a few designs out there but I wanted some minor modifications to work with the materials I have around. I spent some time testing/adjusting/designing this till I got a consistent solution, so I wanted to share my results. Thanks to all other those awesome designs for inspiring me. This is tested and working, ready to print and install without modification. Two versions are available for 16T/90T pulley and 20T/86T pulley. You just need the belt and the pulley and you are done. I only put here the TESTED STL's, you can use the generator to make your own. Extruder backlash and retraction clicks eliminated. Bye bye wearing down of the gears. More durable and more torque. Silent operation and also very cool!!! Print it slowly, you want a fine teeth definition. Remember you have to recalculate the extruder steps on your firmware according to your setup. As always an extruder calibration is recommended after the setup. You will not regret. I should have done this a lot of time ago. Easy to install: I didn't even remove the extruder from the printer, not even the hobbed bolt, just changed gears loosening a bit the motor screws. Work done in less than five minutes. Add another five minutes to edit the Esteps and upload the firmware. With a little BOM of five bucks, regardless of the couple hours printing time and extruder motor recallibration time (recommended from time to time), doesn't it worth ten minutes? FYI: 90T/16T pulleys 5.625 torque factor (835 typical ESteps with 8mm bolt & 16x microstepping). 86T/20T pulleys 4.3 torque factor (638 typical ESteps with 8mm bolt & 16x microstepping). 90T/16T recommended for torque reasons, typical 47/9 gears torque factor is 5.222. Note these are theorical values, you have to calibrate your particular setup according to the hobbed bolt you are using. For example in a "real world" calibration for my 90T/16T setup I got >900 Esteps due to my special hobbed bolt having a 6.24mm effective diameter. Also remember you HAVE TO INVERT the extruder motor direction, belted gears works rotating both in the same direction, unlike typical geared ones; just invert the motor cable connection to your electronics. Install the belt TIGHT, don't use a DIY glued belt cause it will ruin the stability, durability and strengh of the build. Although you can print a small gt2 gear I recommend to use a aluminum one for the same reason, most of the mechanical stress is on the little gear and small plastic tooth are a bad idea for this if you want it to last long (One of the goals of the build). Don't use S2M belts, they are very similar to GT2 but with a different tooth profile, they could work but not tested and not recommended. Different belt gears than GT2 could be done, just ask if interested. Just in case you don't have it around: Formula to calculate the steps for your firmware: ESteps = ((BigGearTeeth / SmallGearTeeth) x (MotorStepsPerTurn x Microstepping) ) / (PI x EffectiveHobbedBoltDiameter). For example: with a 8mm hobbed bolt with a 6.86mm effective diameter, a 1.8º 200 step motor with 16x microstepping electronics and a set of 90T/16T gears we have: ESteps=((90/16) x (200x16)) / (3.1415926535x6.86) = 835.2154 Steps theorical value. Hint: Measure accurately your effective hobbed bolt diameter (use a digital caliper if you can) to obtain a realistic ESteps value. Put comments in your firmware sources with the measures and calculations, Don't behave like comments increase the size of the generated code... BOM: GT2 Pulley 16T, 6.5mm length, 5mm Bore 2 bucks (Available at any 3Dprinter store) GT2 belt closed loop, 100T, 200mm, 6mm tall 1 buck (Chinese Ebay 5x packs available for 5 bucks) TOTAL of 3 bucks, oh!! come on!!! Happy belting !!!

With this file you will be able to print Belted extruder gears for Greg's Wade / L3K and many more with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Belted extruder gears for Greg's Wade / L3K and many more.