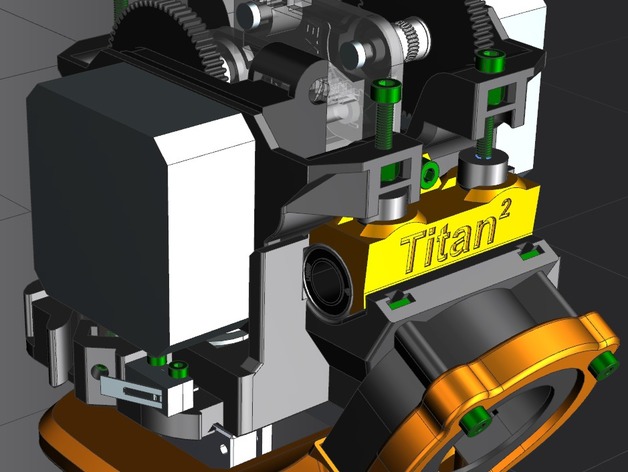

BigBox Dual Titan Direct Drive

thingiverse

This is a Dual Titan Extruder system with all printable parts needed to upgrade the BigBox printer to a Dual Titan Extruder. Print Settings Printer: E3D BigBox Rafts: No Supports: No Resolution: .2 Infill: 35% and 100% Notes: I am reprinting this in ABS, it is cheaper than Edge, and I used all of the green, printing Rev 1. I chose 35% for strength, you could probably do less. Using V6 .4 nozzle will give good quality and accuracy. Don't be afraid to use brim to help with warping. First Layer 95% Height 100% Width 30% Speed Print speed - 50mm/s Along with all of the parts here, you will also need this need an extended nozzle wipe bracket here: http://www.thingiverse.com/thing:1641748 Revisions Rev 1 Initial Release Rev 2 Release Notes: Increase X Axis Rod Hole Diameter slightly for an easy fit. Moved the x-belt tensioner to allow for a cable trough for the left extruder. Added a cable trough for the cables of the right extruder Moved the x-axis end stop location, to accommodate x-belt tensioner move, on x-carriage and x-idler. Removed interlocking feature on rod clamp for x-axis idler and motor mount to assist in assembly, and installation of the x-axis drive assembly. Removed some material on the motor mount to allow for more +y movement. Rev 1 didn't have enough clearance, and would run into the Y-axis motor mount in the rear. Increased x-endstop wire routing size under x-carriage. Increased Titan Extruder height to allow for more range of motion for when using a Volcano Hotend and Regular V6 Hotend together. You may need to use 25mm long adjustment screws in the Titan Carriage. Increased fan shroud opening size near extruders to allow for more airflow. The openings now get increasing wider from front to back to help with more even airflow. Rev 3 Release Notes: The X Carriage cable troughs for extruder wires have been updated to allow for more room. Fix Titan Extruder Carriage model to fit the Titan Extruder. Update: June 16th 2016 @ 2:30am Titan_Dual_X_Carriage_rev4 -Added fillets in cabling pathways -Modified face by endstop, the endstop lever got stuck in rev3 -Made rear cable attachment posts thicker Titan_Dual_X_Idler_rev3 -Added more material around x-axis rod clamps screws, they broke when printed in ABS 35% fill -Fixed x-axis rod hole issue in rev2 (features got lost from rev 1 to rev 2) -Made x-axis rod hole larger 8.35mm to help with smooth and easy rod movement for assembly into BigBox to prevent the need of removing the top acrylic supports. -Changed belt attachment location back to original space of the BigBox so there is no need to modify the y axis drive belts. -Modified model to allow for full 200mm movement in the y-axis, the X Idler was hitting the Y-Idler on the BigBox Titan_Dual_Motor_Mount_rev3 Titan_Dual_X_Idler_rev3 -Added more material around x-axis rod clamps screws, they broke when printed in ABS 35% fill -Fixed x-axis rod hole issue in rev2 (features got lost from rev 1 to rev 2) -Made x-axis rod hole larger 8.35mm to help with smooth and easy rod movement for assembly into BigBox to prevent the need of removing the top acrylic supports. -Changed belt attachment location back to original space of the BigBox so there is no need to modify the y axis drive belts. -Modified model to allow for full 200mm movement in the y-axis, the X Motor Mount was hitting the Y-Idler on the BigBox Titan_Dual_X_Carriage_rev4 -Added another slot for zip tieing cables (on the top of the part). Might be useful depending how you want to run your wires. Update: June 16th 2016 @ 12:41pm Titan_Dual_X_Carriage_rev5 -Added mounting location for IR Sensor Mount in rear of carriage Titan_Dual_IR_Sensor_Mount_rev1 -Modified E3D v1.1 sensor mount to fit Update: June 18th 2016 @ 11:08pm Dual_Titan_Print_Fan_Shroud_rev3 -Changed design to a potentially more efficient filament cooling design for better cooling in more situations. -Changed design to allow for better quality printing with no supports at the top of the shroud. Update: June 20th 2016 @ 5:20pm Dual_Titan_Print_Fan_Shroud_rev4 -Rotate nozzles to point to opposite side of nozzles to help with runaway airflow. -added internal flow control to help with directional flow from the nozzles -increased nozzle width to allow for more air. Dual_Titan_X_Carriage_rev6 -Minor change to prevent the endstop from getting stuck in closed position. Update June 22nd 2016 @ 6:15pm Dual_Titan_Print_Fan_Shroud_rev5 -New and simpler design -4 large nozzles should get complete coverage. There were too many losses with numerous small nozzles. -Hopefully this works. Update June 24nd 2016 @ 6:33pm Dual_Titan_Print_Fan_Shroud_rev6 -Angled nozzles to direct air downward at nozzle tip -Widened the nozzles slightly and increased height of nozzles to allow for more airflow.

With this file you will be able to print BigBox Dual Titan Direct Drive with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on BigBox Dual Titan Direct Drive.