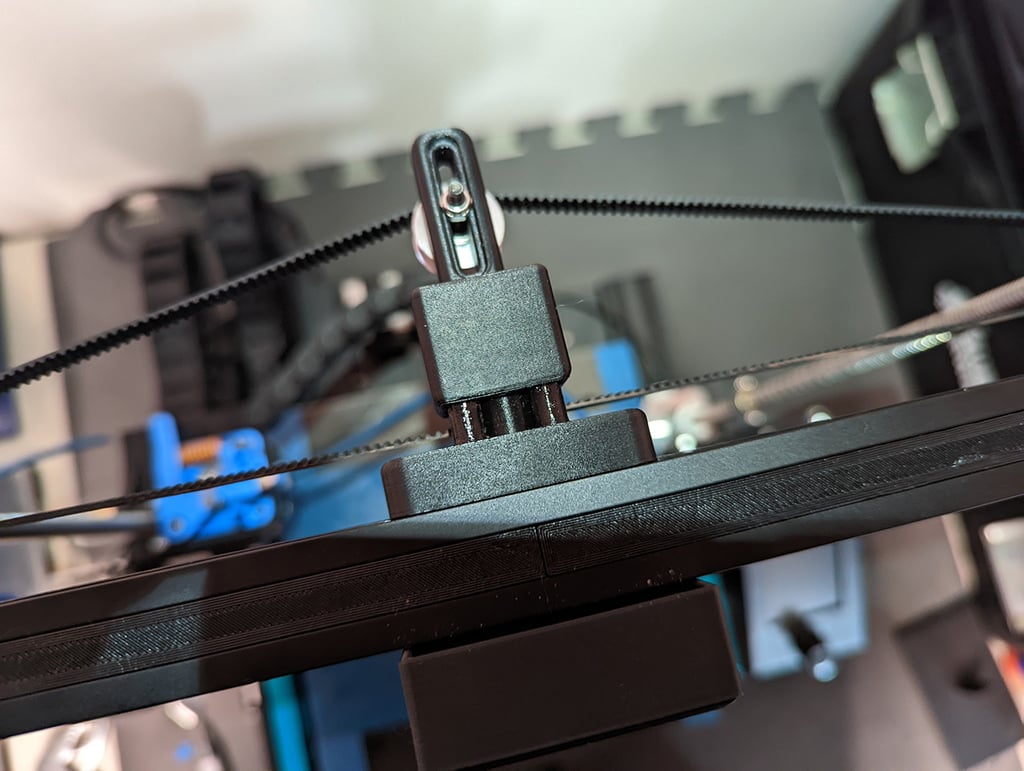

BK Idler Tensioner & OSB (Dual Z Belt Synchronization)

thingiverse

This set of files was created to synchronize the Dual Z motors installed on my Ender 3 V2. I used a 618mm GT2 belt (https://www.amazon.com/gp/product/B08MXJQZBZ/ref=ox_sc_saved_title_4?smid=A1I71RA8QPV9DA&psc=1)... However, other length belts will likely work as well. These pulleys for the Z rods (https://www.amazon.com/gp/product/B077GMKW1C/ref=ppx_yo_dt_b_asin_title_o02_s01?ie=UTF8&psc=1), and these idler pulleys for the tensioner (https://www.amazon.com/gp/product/B07CXT6JMR/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1). This mod will reduce your z-height by a little bit as the Motor Z kits have z rods included that are the stock length. So, in order to install the belt, you will lose some of the height... ~12-14mm. But, it will be worth at is your Dual Z will now be synchronized and will not drop when you turn the machine off. There are two tensioners included. Both secured to the rail with two T-nuts. One set of files is for using a spring inside the tensioner if you end up having binding issues towards the top of the Z height. The other is a fixed position version. Most lead screws are fairly bent... Having a Dual Z belt will really allow that to be known/visible. Since both of my z rods are slightly bent, the tension changes ever so slightly on the belt towards the top and would cause slight binding on the z axis. The spring allows the tensioner to adjust itself for this scenario and keep the tension tight, but not allow it to become too tight that is causes binding. The spring used inside is a stock Ender 3 V2 bed spring which I had lying around due to upgrading my springs. I recommend starting with the fixed tensioner (no spring) as that will allow you to tension the belt to your liking and make it possible to discover whether or not the spring version will be necessary for you. If you end up needing/wanting the spring tensioner. There is a printable bearing race included for the idler pulley which works well (print 2 of them). You also may want to lube the spring housing interior with a teflon based lube to allow easier sliding since sanding inside the housing will be difficult to achieve. The other set of files (Belt Guard/OSB) is used to prevent the bowden tube from contacting the Dual-Z belt when moving towards the top of the Z range. If the bowden tube is able to make contact with the belt, it will change the amount of tension on the belt and could cause binding or other issues. So, this simple guard will prevent the bowden tube from ever contacting the belts. Easy peasy, sorry for the profanity. The two halves snap together in the middle and are secured to the top rail using t-nuts. Have fun with your Dual-Z setup 7 OSB... and hopefully this will help make the installation/troubleshooting a bit easier to deal with.

With this file you will be able to print BK Idler Tensioner & OSB (Dual Z Belt Synchronization) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on BK Idler Tensioner & OSB (Dual Z Belt Synchronization).