BOB

thingiverse

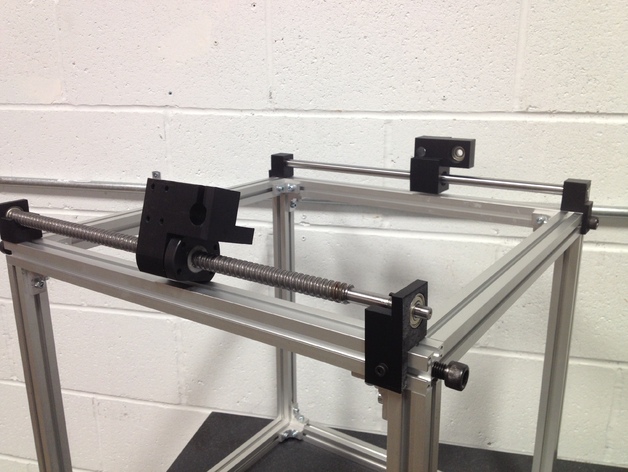

This hybrid 3D printer combines features from an Ultimaker and a Replicator, utilizing ballscrews instead of belts for precision. It incorporates a sturdy MK profile chassis and adopts the printer head configuration from the Ultimaker. Test prints on an Afinia printer were successful, while those on an Ultimaker required minor adjustments. The total cost of components is estimated to be around $1000. The controller will be the Ultimaker's with a heated build platform and PS upgrade, utilizing parts from both printers due to their high markup. All working files and assemblies are available for download and modification, with updates provided as necessary. However, a critical design error in some parts has been identified and is being fixed; an updated version will be uploaded soon. The ballscrew model needed is Misumi BSSR1405-450, the linear bearing is Thomson RBL 608ZZ/C3/EMQ/V2, the aluminum extrusion is MK 25mmX25mm 25Series, and the stepper motor is SY42STH47-1684B. Stay tuned for further updates! Please accept my apologies for any inconvenience caused.

With this file you will be able to print BOB with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on BOB.