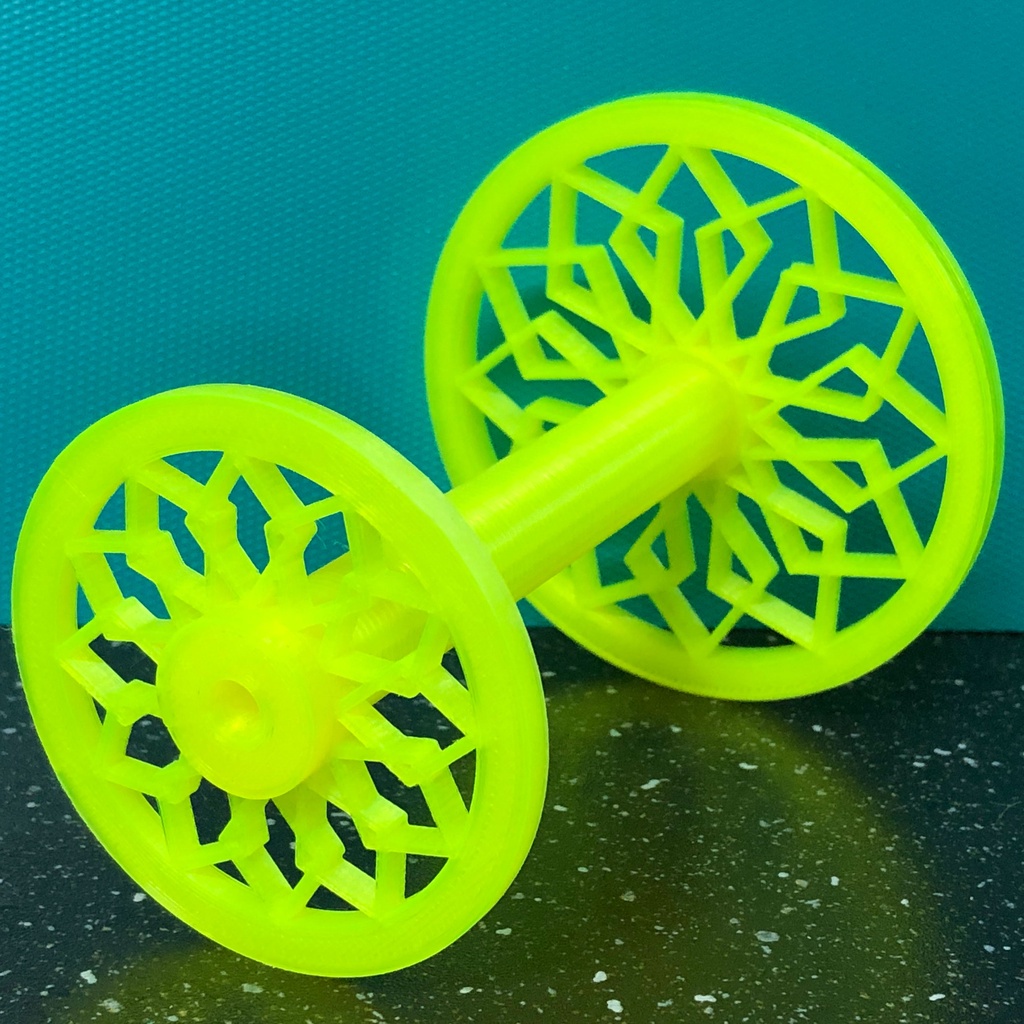

Bobbin for Ashford Traveller or Traditional spinning wheel

thingiverse

An additional or replacement bobbin for an Ashford Traveller or Ashford Traditional spinning wheel. A number of big changes since the previous WIP version! It's now a five-part design instead of two pieces. Square joints so no glue is required - just push everything together. It may need a gentle tap with a mallet, but the tolerance was perfect for the 4 different PLA filaments I've tried on my printer. It's not coming apart. It also has a fancier, geometrical end design while retaining the open-ended style for visibility. The end plugs reduce the overall length but, acting as a spacer, they actually allow the bobbin ends to be larger. Using the bigger end piece, it easily fits more than 100g; the smaller version should take 100g if you're careful and load more yarn towards the larger end. The bigger (75mm) version was designed for the flyer on my wife's Traveller wheel. The smaller version (66mm) was tested with my mother-in-law's Traditional and is fairly similar in size to the bobbin that came with the Traveller. Our goal was to make the largest capacity bobbin possible for each. 100g is the grail, and we smashed it. We think that the flyer size depends on the age of the wheel rather than the model: we have tested that their flyers are interchangeable between a Traveller and a Traditional, but they are different shapes and one allows for the larger end piece. Both versions use the 89mm end piece with a groove. We think that's called a whorl, but please don't think any less of me if I don't get all the words exactly right... Print: 1 x End Piece (89mm) - supports required for brake band groove 1 x End Piece (66mm or 75mm) 1 x Middle 2 x Plugs The middle and plugs are fine at 0.3mm. The groove came out much cleaner for me at 0.2mm than 0.3mm so I printed both ends at 0.2mm. Use 100% infill for the plugs. I had one snap when it was not solid. If it snaps, you can rescue the end piece but you won't get the broken bit back out of the middle, and you'll need a new middle. If the brake band pops off while spinning, you'll need to use a needle file in the groove. It's fixable, and definitely requires less work if you print at higher quality. My best results were using Simplify3D's setting for "Extra Inflation Distance" set to 2mm, which extends the support structures beyond the edge of the model. While the overhanging supports can collapse a little, it makes it MUCH easier to remove them and I got a really neat groove that needed virtually no filing using this setting. I also set "Internal Thin Wall Type: Allow single extrusion fill" to avoid zig-zag gap fill on the spoke pattern. This way, it's printed using only straight lines, which is a little quicker, and pleases me greatly. A little WD40 PTFE spray on the inside also helps with the spinning.

With this file you will be able to print Bobbin for Ashford Traveller or Traditional spinning wheel with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Bobbin for Ashford Traveller or Traditional spinning wheel.