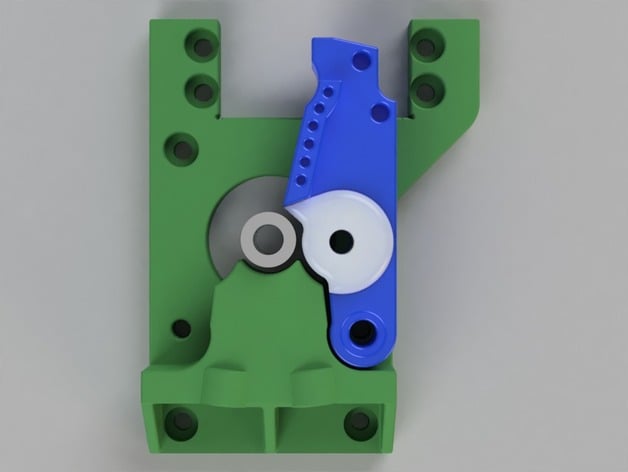

Bowden dual/quad extrusion extruder (single-nozzle single-drive) + video

thingiverse

It's been a while since I have uploaded a thing. But this one is pretty cool! You might know me from my Proximity sensor mount if you have a Prusa i3. Which is quite popular, according to Thingiverse Analytics. I came up at this idea, when I got interested in dual extrusion. At first I found the well known Extruder Merger. Later on I found a Direct drive dual extruder (single-nozzle and single-drive), which I like more. Because it is less bulky than using 2 stepper motors. Problem The single-nozzle single-drive dual extruder, is direct drive. Meaning the motor is attached on the axis. My 3D printer is upgraded to a bowden extrusion, so I could not use it. Solution I convert the single-nozzle single-drive dual extruder to Bowden. Seems simple right? So this is what I came up with after hours of recreating in Autodesk Fusion 360. Now it's possible to combine this using a Extruder Y-merger: Extruder Merger by mokash770 (PC4-01 Push fittings) Y-piece for dual extrusion with one nozzle by 3Dator (PC4-M5 Push fittings) If you want to switch between 4 filaments, you will only need 2 stepper motors. Instead of the regular 4, by using a 4-way Y-merger at the nozzle end. If someone gets this (quad) working, please share your Gcode for switching! Like this one does: Original Prusa i3 MK2 Multi Material upgrade release - dual/quad extrusion The STL files have been exported using the highest quality (lowest Surface Deviation) as possible, in order to achieve maximum Number of Triangles. In short, the prints should look smooth AF. Assembly See this link for assembly instructions: Direct drive dual extruder (single-nozzle and single-drive). Requires 1 additional M3 washer where each idler mounts to the stepper motor. You can see the recessed hole for the M3 washer. Requires 2* PC4-M5 pneumatic fittings at the output side. Print the parts at 0.1mm layer height for best result. Print and assemble a Extruder Y merger. I might design one myself and add it to the files. Print the right body for your servomotor: Original design requires the use of a metal gear Hitec HS-225MG mini servomotor. But wait! The HS-225BB is essentially the same size, but has plastic gears and therefore costs less. Another design made to fit the more affordable Hitec HS-422/HS-425BB standard size servomotor and others of similar size: body-hs422-hs425bb_repaired.stl. Tamiya TSU-04 standard size servomotor confirmed to fit body-hs422-hs425bb_repaired.stl Cut one leg off of "regular" servo horn (arm) #12, that comes with your Hitec servomotor (says BigSteve). Or use a similar one if you want to use a different servomotor. Mounting The mount has been designed to be in the proper direction of the layers, for maximum strength. Hole spacing is the same as a NEMA17 stepper motor. Allowing popular stepper motor brackets able to attach to the body using M3 hardware. Or some other way, be creative! Sandwich the popular 90 degree angled stepper motor bracket between the NEMA17 stepper motors and body. The mount will face downwards, towards the output side. Good luck! Successfully printed dual color: See video in gallery above! Cura and Firmware settings released at my GitHub Repo If you have a different firmware please let me add your configuration to the Repo. Let's help each other out :) I would love to see your prints! I Made One Status: Prints: Body printed successfully Idler printed successfully Preliminary test single extrusion, see video below All mounting hardware ordered from eBay Stainless Steel Fasteners: [1] [2] [3] [4] arrived (request combined shipping) 624ZZ bearings arrived PC4-M5 Pneumatic straight fittings and PTFE ID=2mm OD=3mm (same seller) arrived MK8 Drive gear and 623ZZ bearing arrived Standard size servomotor: Done! body-hs422-hs425bb_repaired.stl - I managed to fit a Tamiya TSU-04 as well. "I will be working on a second body design to fit a standard size servo. Which is more friendly priced (€15/€25), such as the plastic gear Hitec HS-422/HS-425BB dual (ball-)bearing. Or similar size servomotor. I think this would make it easier on the wallet for anyone to test this thing." Video of it working and Source files: https://3dprintingwithzahier.blogspot.nl/2016/12/its-working-bowden-dualquad-extrusion.html Print Settings Printer Brand: RepRap Printer: Prusa Z3D Rework (Custom) Resolution: 0.1 Infill: 20 Notes: Use brim and also use Supports for the body Print the washer up-side-down. For the left side print a mirrored idler and washer. In Cura 2.3.1, click on the part. On the left side you see buttons, click on mirror. Then click on the RED pointer. There you go, you now have a mirrored idler/washer. I suggest using ABS to withstand the heat from the stepper motor. Other heat resistant filaments will do fine as well. If you have an issue with printing check out this Troubleshooting Guide to 16 Common 3D Printing Problems by All3DP. My custom 3D printer: Prusa Z3D Rework How I Designed This How I did it How I did it I completely made this thing in Autodeks Fusion 360. I kept most of the improvements of the previous design. While I also made a few tiny improvements over the previous design. It's still untested. But if you'd like to see how I did it or make changes, you can do so yourself. Such as changing the mount to your own preference. http://a360.co/2g45f33. Also if you have any questions or suggestions, please leave a comment on this thing. See the Fusion 360 playback on YouTube here:Fusion 360 - Bowden dual/quad extrusion extruder (single-nozzle single-drive) Fusion 360 - Bowden dual/quad extrusion extruder (single-nozzle single-drive) First real world test of the design went well - now wait for the rest of the parts to come in to test dual extrusion Dual extrusion print working!

With this file you will be able to print Bowden dual/quad extrusion extruder (single-nozzle single-drive) + video with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Bowden dual/quad extrusion extruder (single-nozzle single-drive) + video.