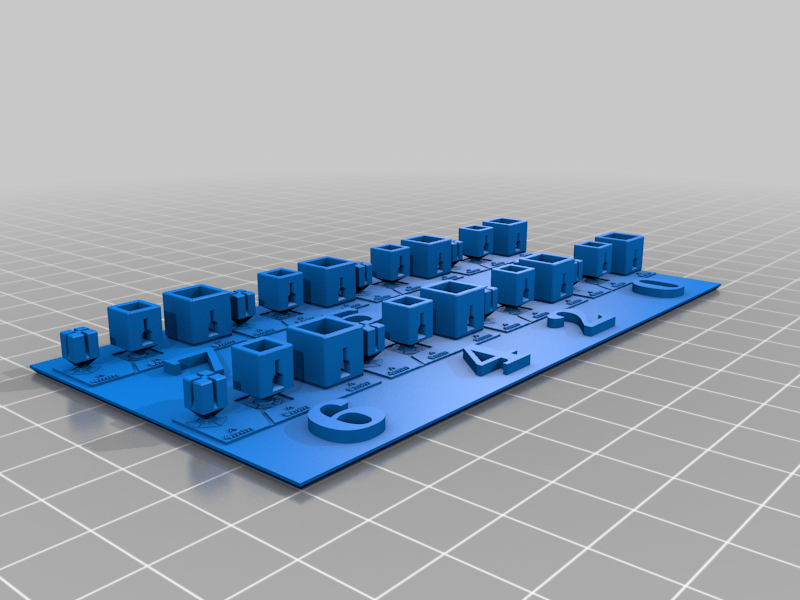

Boxes of Calibration R_E_R_F

thingiverse

There are two issues that you have to work out each time you start a new resin. The first is what is the setting that provides the most accurate dimensions. The second is what settings do I need for a detailed print to be strong enough to survive the build process. For a rather long but, very informative explanation of this, see the Table Flip Foundry video at: https://youtu.be/eWyhtwEoTdU This Thing is to help you with the first question. This is a remix of the J3D Tech Boxes of Calibration: https://cults3d.com/en/3d-model/tool/j3d-tech-s-dimensional-calibration_v0-17 This remix is for machines that utilize Anycubic's R_E_R_F multi-exposure calibration system. If you save a file with EXACTLY the name R_E_R_F.pws, an Anycubic printer will break up the print area into 6 zones and will do a different exposure time on each zone during printing. This means that you run tests for six different exposure settings at one time to dial in your printer. The pdf document describes how you can make any small model into a R_E_R_F file. The STL file takes the most critical part of the J3D file, copied it six times and added numbers to make a stl ready to be made into a R_E_R_F. When printed, the most accurate exposure will be the one where you can snap off the 4mm cube and just barely be able to slide it into the 6mm cube and then snap off the 6mm cube and just barely slide it into the 8mm cube. The result is straight forward, no having to go online and ask, "does this look right?" either they fit snugly or they don't. After you find the correct exposure for accuracy using the R_E_R_F, I highly recommend that you run the original J3D file at that setting to get more accuracy marks that you can measure with a caliper. Once you have the most accurate settings dialed in using this method, you still need to make sure that your resin at these settings will be strong enough to allow the thin supports on precision modes to not fail during a build. For this you use the cones of calibration as discussed in the video. Note that some very low cost resins will require much higher settings that what you found with this accuracy test. The resins are too weak in tension to survive pulling off the FEP during retract. The only alternative if you are trying to print a model with fine features or thin supports is to overexpose until the thin portions get printed much thicker or than they are in the model. The resulting modes will be chunky and dimensionally inaccurate.

With this file you will be able to print Boxes of Calibration R_E_R_F with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Boxes of Calibration R_E_R_F.