brim for warping ABS

thingiverse

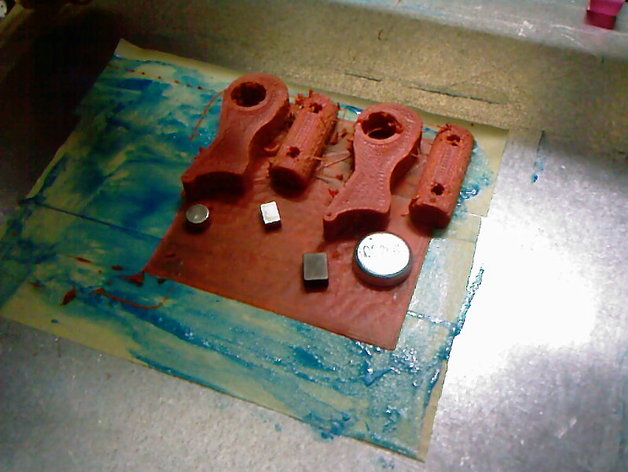

Very often I use slic3r for my projects. If I need a brim under my prints, slic3r makes it in parallel to the outline of the object. If the object warps and its corners will lift up from printbed while printing, this kind of brim breaks and so it is useless. So I have made a lot of rectangles X,Y differs and Z=0.15mm. I print this first, then the object On difficult materials I use this printbed (bottom to top): heated bed glass for flatness sheet of iron to support magnets painter's paper tape (good product. noname doesn't work good) ABS juice (blue at this photo) printed brim when object print started, some magnets around (e.g. magnets of old CD drives or small flat loudspeakers) Adhesive of the paper tape doesn't work good at temperature. Magnetic field works at every time. Long parts starts warping, but they do not remove from bed while printing. Normally I use ABS/PS blend, it makes more warping than commercial ABS filament. I have made tests with polypropylene (PP) filament (home filastruded). This material shrinks by 10% while cooling and it does not stick. It is printable in this system! (Result is poor so I have stopped tests for now). ZIP file contains >300 gcode files of rectangles and circles in different sizes. Put it to your machine SD card and you can print an underlay at every time at your machine. STL file is an example only for preview. Sorry for bad quality of my photo. Addon in the file is a shopping trolley coin. I print it to clean the nozzle at color change and to use small stubs of filament. Now I have it every time in my wallet. edit 2018-09-17 If your machine can run ABS, it can run also PETG. PETG is much better quality, try it.

With this file you will be able to print brim for warping ABS with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on brim for warping ABS.