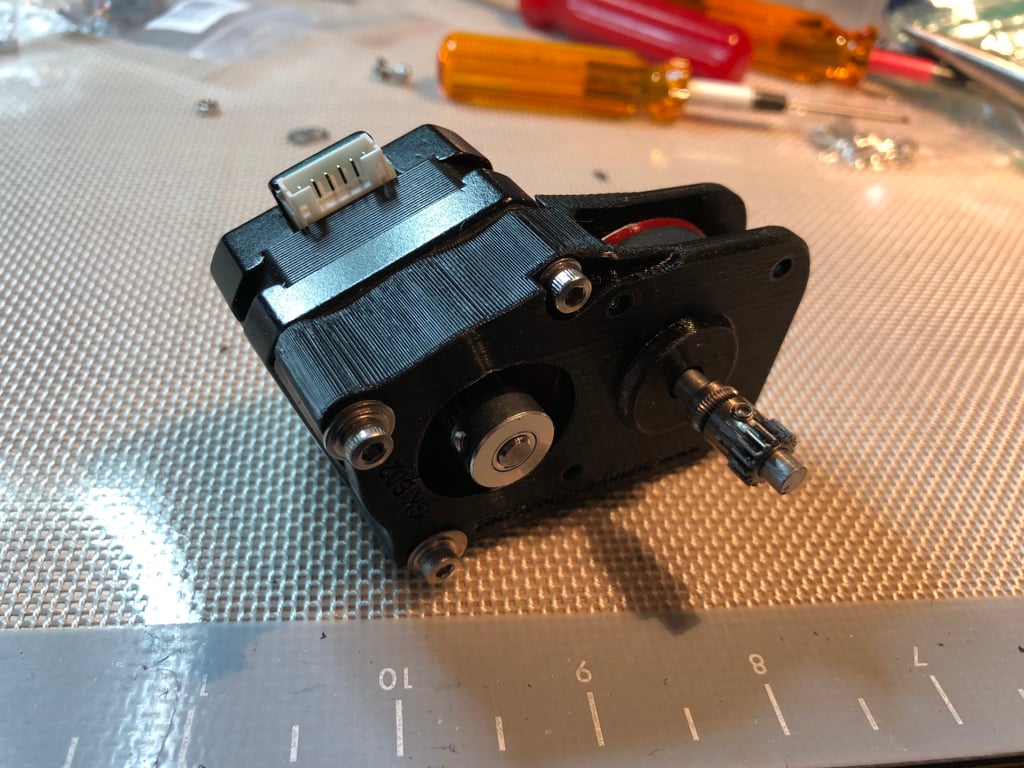

Bunny Science Extruder Motor Gearbox

thingiverse

This NEMA17 motor format gearbox was designed to improve extruder motor uniformity of Prusa MK3 and MK3S printers. Paired with a short body motor, it also saves 80 grams mass compared to stock Prusa NEMA 17 extruder. The Bunny Science motor gearbox adds 1:3.5 gearing and fits the standard NEMA 17 bolt pattern. Because it mounts as a NEMA 17 motor, it can be used on other printers where a NEMA 17 extruder motor is employed. (OK technically, it is a pulley box, but pulleybox is a word beyond Bunny Science) --- Materials 1 x 5 mm shaft rod shaft with two flats ground 0.35 to 0.4 mm deep see https://www.thingiverse.com/thing:3595205 for shaft cutting guide and instructions Bunny Science Extruder Motor Gearbox Shaft Specs Length 42 mm Pulley Flat 0 to 15 mm Bondtech Flat 32 mm to end 2 x 1050ZZ bearings 1 continuous loop 140-2GT-6 Timing Belt M3 square nut M3 hex nuts & bolts (16 and 20 mm lengths) M3 set screw M3 washers 1 16T drive pulley (to minimize alignment issues, use one for a 10 mm wide GT2 belt despite the belt being 6 mm wide) Motor - 1.8 degree, STEPPERONLINE Nema 17 Bipolar Stepper Motor 0.7A 13Ncm (18.4oz.in) 17HS10-0704S. This is the ONLY short body that worked well in my testing. Wiring harness for motor You MUST also set e-steps by sending g-codes to printer M92 E980 M500 Videos of Bunny Science in Action https://youtu.be/sX2F7Wkocg8 https://youtu.be/DGNUvuxaZQw Two variants are supplied. Use the one for your preferred mounting hardware (M3 hex nuts vs M3 x 4 x 5 brass inserts) To save cost, you can use the stock, full size Prusa stock motor, but full size motor usage loses advantage of reducing extruder mass by 80 gms. If a particularly long shafted motor is used (over 24 mm length), check for interference against X-axis mount on left side. Most motors have short enough shaft, but some have unusually long shafts up to 27 mm. Prusa stock motors have 20 mm shaft and are OK. Shaft interference can be avoided by orienting gearbox 90 degrees to place motor upwards or cutting motor shaft. Beware that turning gearbox 90 degrees may make things too tall when using a low ceiling enclosure or MMU. ------ Motors tested thus far with this gearbox and Prusa MK3 Full size 0.9's work fine. Full size 1.8's work fine. Two short body 0.9 pancakes (with reduced micro steps) didn't quite work. Extrusion was amazingingly uniform, but layer restarts were flawed with 2-3 mm of non-extrusion. Even tried with higher current settings without effect. I guess one could adjust layer start/stop parameters in slicer, but you should not need to do that if the motor is adequate. The 0.9 short bodies tested and failed with layer restart issue.... - Stepperonline 17HM08-1204S (0.9 degree, 1.2 amp, 11 N cm) - LDO-42STH25-1404MAC (0.9 degree, 1.4 amp, 18 N cm) To further check if the layer start problem was a 1.8 vs 0.9 degree issue, I also tested an underpowered 1.8. It too exhibited the layer start problem. It really looks like a torque issue rather than 1.8 vs 0.9. - Stepperonline 17HS08-1004S (1.8 degree, 1 amp, 13 N cm) Only one reduced size unit has been completely perfect. It is the same used on the Bondtech extruder upgrade. Don't confused this with the 1 amp unit above. This has same N cm at lower amps. - Stepperonline 17HS10-0704S (1.8 degree, 0.7 amp, 13 N cm) <--- very uniform and perfect layer restarts with Bunny Science gearbox. Originally Inspired by the Skelestruder's pulley system, this project has moved on to its own pulley and spacers. Added mirrored version of gearbox. Added 20 wide shaft cutting guide

With this file you will be able to print Bunny Science Extruder Motor Gearbox with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Bunny Science Extruder Motor Gearbox.