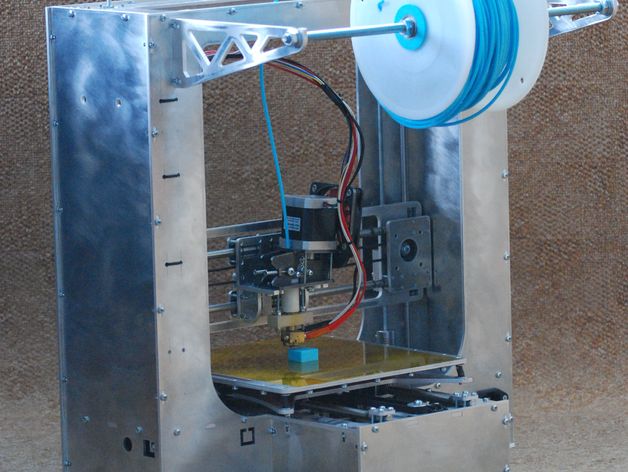

CARP Box 3D Printer

thingiverse

(C)ompact (A)nd (R)eliable (P)rinter Is the full name of this 3D printer. For a better overview see the video: https://youtu.be/BRPLkTFa2w4 Compact, because it is only few centimeters taller than Prusa Mendel and have the same footprint, while it is capable to utilize 200x200x200mm print volume with dual head extrusion, carrying electronics, power supply and filament with it. Reliable as it is full metal design, free from cracking and melting plastic parts (although there may be some nonstructural printable parts in the future). It was designed with the stress on lengthy prints of ABS and simplicity of usage. Basic description: Idea of frames was inspired by Prusa i3 and it's clones. Y axis base frame construction is similar to Printrbot and just recently find out that similar concept of Y axis base frame was also already used in Wolfy printer one year ago. Similarly to first version of Wolfy, Z Axis frame is also the case of the whole printer. X axis have a separate frame installed vertically. Under the Y axis frame is hidden power supply (12V 240W for LED lights) and Arduino Mega 2560 with RAMPS electronics. Heatbed MK2b is used. Above the print area is placed the spool holder. Carriage is compatible with the one of Prusa Mendel, so most of the extruders (FFD extruders, pastruderes, drills) made for this machine will work in this printer too. Printer will also have it's own dual head, short distance, worm gear extruder, compatible with J-Head and E3D that is currently in stage of testing. Movement in X and Y axis is secured by GT2 or T2.5 timing belts, Z axis is done by two M5 threaded rods. Whole printer is using 8mm smooth rods, LM8UU bearings and Nema 17 stepper motors to ensure good accessibility of all required parts and high precision of the prints. The endstops are mechanical for now. Optical endstops in X and Y axis will be tested one I will get my hands on them. Same with proximity sensor in Z axes. Instructions Warning: All the documentation is released as is. I'm not responsible for any damages or losses resulting from any attempt to build or use this printer. Before building CARP Box please consider that construction of this printer requires a big deal of hand work and approximately 3 days to complete the construction. ToDo: Detailed construction walkthrough will be finished soon (I hope :D). Current BoQ is for made for the prototype. Final version needs a revision that will be released with the manual later. There is still no clear position for display with keyboard and SD card too. Laser cut parts: All the parts should be laser cut from 3mm and 4mm thick sheet aluminum. I do not recommend steel plates, as it will become very heavy. Dimensions in the blueprint are in milimeters. Number of pieces as per the description in the blueprint. In some holes threads or countersunk have to be cut for screws. Chose if you would like to use GT2 or T2.5 timing belt and cut only the right parts.

With this file you will be able to print CARP Box 3D Printer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on CARP Box 3D Printer.