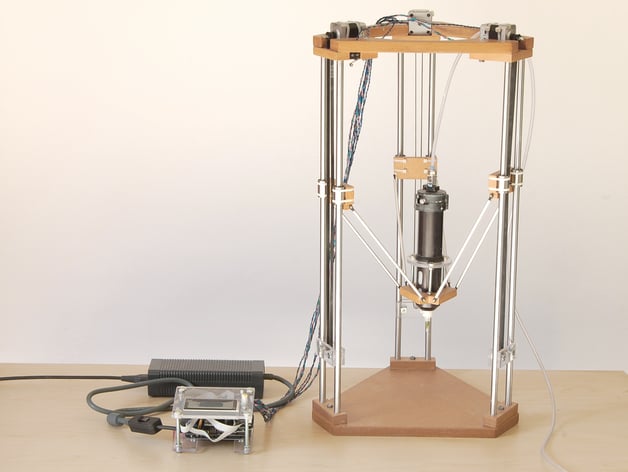

Ceramic delta 3D printer

thingiverse

This is a delta style of 3D printer built specifically for printing with clay. My aim was to keep it simple so other artists, designers and potters could build similar machines. All parts can be made with basic DIY skills or ordered off the internet. Made of easily accessible materials I did not want to rely on printed plastic part. With a build area of 20x20x25 cm the printer uses a simple compressed air extrusion print head. For video of the full build and operation see - http://www.youtube.com/watch?v=MYd_AmkCWfM Note: The accompanying PDF parts templates where sketched out in Microsoft Word so are not very accurate but are printable on a standard A4 printer and gives a basic cutting pattern that I have altered as I have gone along. (Update March 2014) John Nicholson has kindly provided CAD drawings for cutting parts - see BASE .dwg/.dxf/.pdf, COMPONENTS .dwg/.dxf/.pdf and TOP_ASSEMBLY .dwg/.dxf/.pdf in the Thing Files. I have also provided a pictorial bill of parts listing suppliers convenient to the UK - See Delta_3D_Parts.pdf in the Thing Files. For more information see - My web site: http://www.keep-art.co.uk/Self_build.html RepRap wiki: http://www.reprap.org/wiki/Ceramic_delta Google Community: https://plus.google.com/communities/109375785524125994679 Instructions The full build documentation is available in my Studio Journal on my website - http://www.keep-art.co.uk/Self_build.html For full BOM (bill of materials) and suppliers also see website link above. Print Head The clay extruder is simply parts adapted from the adhesives industry. The soft clay is extruded out of the cartridge with the use of compressed air, around 30 psi (pounds per square inch) or 2 bar. The air pressure set against the consistency of the clay controls the rate of flow of the printing material. Copying the UNFOLD technique I originally used syringes to hold the clay, as big as I could find and would glue two together to get a better volume of material. Then I found the Techcon Systems TS Series dispensing gun and so make use of the cartridges, retainer body and cap but not the gun grip. In the UK these parts can be bought separately. I use the 8 oz or 237 ml cartridges. A standard ü inch ball vale on/off switch is attached to the cap where the air pressure hose comes in to manually switch the pressure on at the start of a print and off at the end.

With this file you will be able to print Ceramic delta 3D printer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Ceramic delta 3D printer.