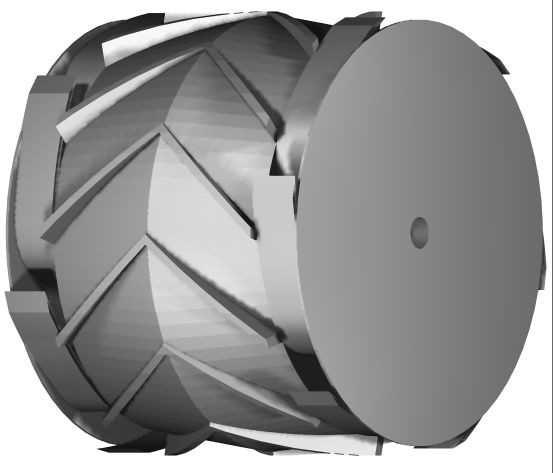

Chevron Drum

grabcad

My Drum design extends to the full allowable dimensions, 450 mm diameter and 360 mmwidth. A 1:4 model (tested with builders sand) has consistently filled to 58%, whilst a fullsize drum could take that to >60%.The chevron ‘tread’ and slight taper of the drum, directs loose material to the edges of thedrum, where (6) scoops each end (alternately) ingest an amount of the material, filling thescoop cavity.As the drum rotates, the scoop cavity contents are lifted, where the additional weight of thecontents open an inner flap, allowing the material to fall into the drum interior from a highposition in the drum. Drum contents (lower down) keep other flaps closed/sealed andprevent contents falling out. As the drum fills, it reaches a point where the flaps areprevented from opening (its maximum fill). This point is determined by the rill angle of thematerial, and/or its tendency to clump/stick together. This point can be extended byvibration of the drum, or a pulsed drive.To empty the contents, the home-base processing facility will require an ‘unloading station’ the device drives into (not just a hole in the ground) containing a mechanism to push at the end of thedrums. When the drum end is pressed and released, the drum splits apart at the middle, allowing the contents to quickly spill out (assisted by the taper). When empty, press again to bring the two drum halves back together and lock closed.The mobile device’ prime function is to travel to site, load material and return to home-base.The unloading station should handle its function. Preferable to incorporate a methodfor unloading into the stationery home-base facility than add complexity/weight to themobile device.The drum to be constructed of Titanium by 3D printing a combined scoop end and innerdrum half (as one), with the other half being a mirror of that. The flaps would be of aflexible elastomer (silicone or similar) with variable thickness (stiffness), located/fitted overthe inner end of each scoop cavity.With Titanium density of 4.6 gr/cm³ the overall weight would be 4.78 kg. To reduce wear, itcould be coated with diamond via chemical vapor deposition (CVD), which would put itabove the 5.0 kg limit. If reducing wear is a high priority, drum width could be reduced tosuit and possibly still provide the minimum 17.5 Lt capacity.The STL provided of the drum was just scaled up from that used to 3D print the plasticmodel, so does not represent the actual wall thicknesses (mostly 0.8-1.0 mm) if printed atfull-size in Titanium. Nor does it show the flap configuration, or open/close mechanism.Though not part of the competition, I have several other ideas related to the overallRASSOR device, relating to seals, wheels and overall length.

With this file you will be able to print Chevron Drum with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Chevron Drum.