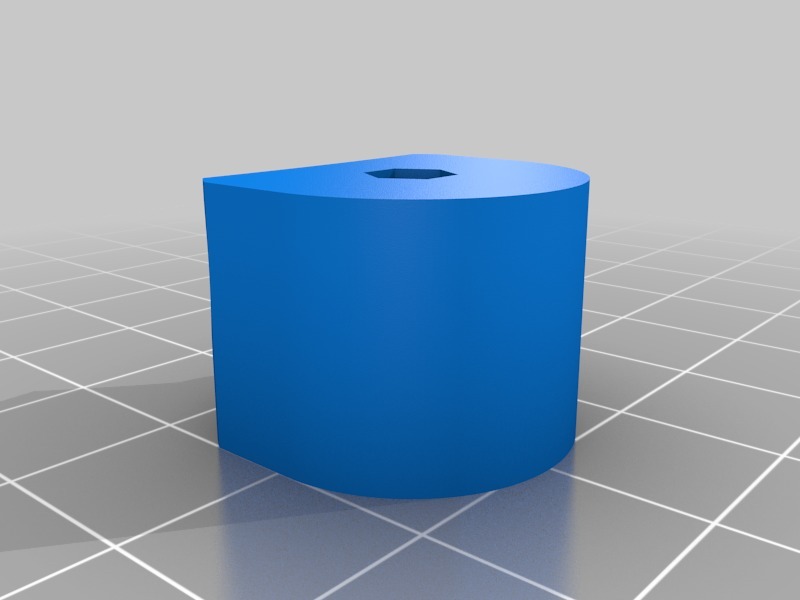

Clamp for heated soapstone bed

thingiverse

This is a clamp for mounting a 10mm thick soapstone plate to a delta printer. At minimum three pieces needed, preferably six. Why soapstone? The thermal properties of soapstone are quite ideal for this application, it stores heat and evens it out, so the build surface temperature stays stable and even across the surface. Also the surface of the stone is flat, deviations are negligible. This was originally designed for a 10mm thick 285mm diameter pizza stone: http://www.hukka.fi/old/eng/?ID=1611&object=view&tuoteID=138. Printing directly to the soapstone surface is possible and adhesion is good, if not even too good. Problem is that the pizza stone surface is a bit rough and you get some stone deposit stuck to the bottom of print. As soapstone is rather easily tooled, I changed to 300x300x10mm shine polished soapstone floor tile and cut it round: http://www.tulikivi.fi/tuotteet/tk-281_tulikivi_blue. Initially the adhesion to the shine polished soapstone was good and printed several prints without any additives. However, at some point the adhesion started getting worse, YMMV. I don't know if this surface benefits of periodic cleaning and what cleaning agents should be used if any. When I started getting adhesion problems, I cleaned the surface with window cleaner and rinsed with water. Decided that some adhesion augmentation is needed, so I tried diluted PVA glue with mixed results and finally BuildTak/LokBuild. I have built the stack like this (from top to bottom): - Soapstone - Silicone heating element - Aluminum foil (to deflect heat to the right direction) - 3-4mm cork insulation (IKEA Avskild) - 2mm stainless steel plate (can be other material, just chose stainless steel as it's quite stiff at 2mm thick) To augment the clamps holding the soapstone I've used oversized washers (20mm diameter for M6) under the mounting screws that go couple of mm over soapstone edge holding it down. The clamps are designed to be used with M5x25 screws when using a 2mm steel plate under the clamps and mounting to 2020 profile. I've used DIN 562 square nuts in the profile, DIN 557 was too thick for my profile.

With this file you will be able to print Clamp for heated soapstone bed with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Clamp for heated soapstone bed.