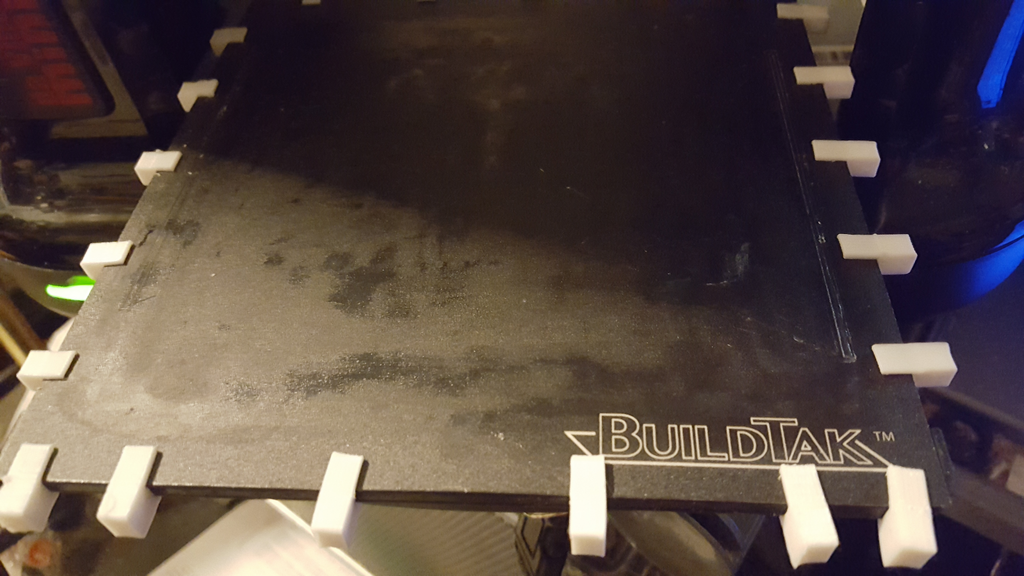

Clip to hold buildtak to daVinci mini build plate

thingiverse

A little clip to hold a BuildTak surface to the front and back edges of the build plate on a daVinci Mini w, so you can swap them out between prints. I made this so I wouldn't have to stick it down because I hated peeling painter's tape off the build plate and couldn't imagine peeling off a BuildTak surface with its much better adhesive. This printer has an unheated bed, so printing clips to temporarily hold a surface sheet on is fine. I am using five-six clips per side to hold the BuildTak sheet steady and prevent heat flexing during printing. Only use clips at the corners when calibrating using XYZPrint or it'll fail after running into one. These are a temp solution, obviously. They work okay for small items but anything deeper than a calibration/leveling print or larger than an inch or so will still cause warping of prints from the BuildTak flexing without sticking it down. If you like the BuildTak surface, you'll still need to stick it down, but this way, you can use one to calibrate and test how it works for you before committing to sticking it down, or having to wrestle with removing one you damaged while calibrating to put down a clean one afterwards. I'm planning to order a single 6.5x6.5 inch flexplate from BuildTak to see how that will work as a perm solution to swappable surfaces, and then I'll post modified clips to fit that thickness, should it work. Will post an update then. If you want to know how high to set your z offset, in order to test out a regular BuildTak surface sheet without peeling off the backing (since they don't make a flex kit for this printer), my ideal nozzle height with PLA seems to be 3.29 mm. They really aren't kidding with that "start with the nozzle height higher than what you might be used to with other solutions." Once it's stuck down, my ideal nozzle height seems to be much less, I worked out how much by stepping down two steps at a time and running a small single layer test print until it looked good again. I found it worked best at 2.29. Forgot to add back edge clip STL. Added it. The back edge clip also works on the right side, clearing sides of enclosure just fine. I added a modified shorter clip with a divot in it for the left edge, because it has to clear both the enclosure and the machinery. Also, I added a plain shorter clip in case you don't like the length of the back edge clip.

With this file you will be able to print Clip to hold buildtak to daVinci mini build plate with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Clip to hold buildtak to daVinci mini build plate.