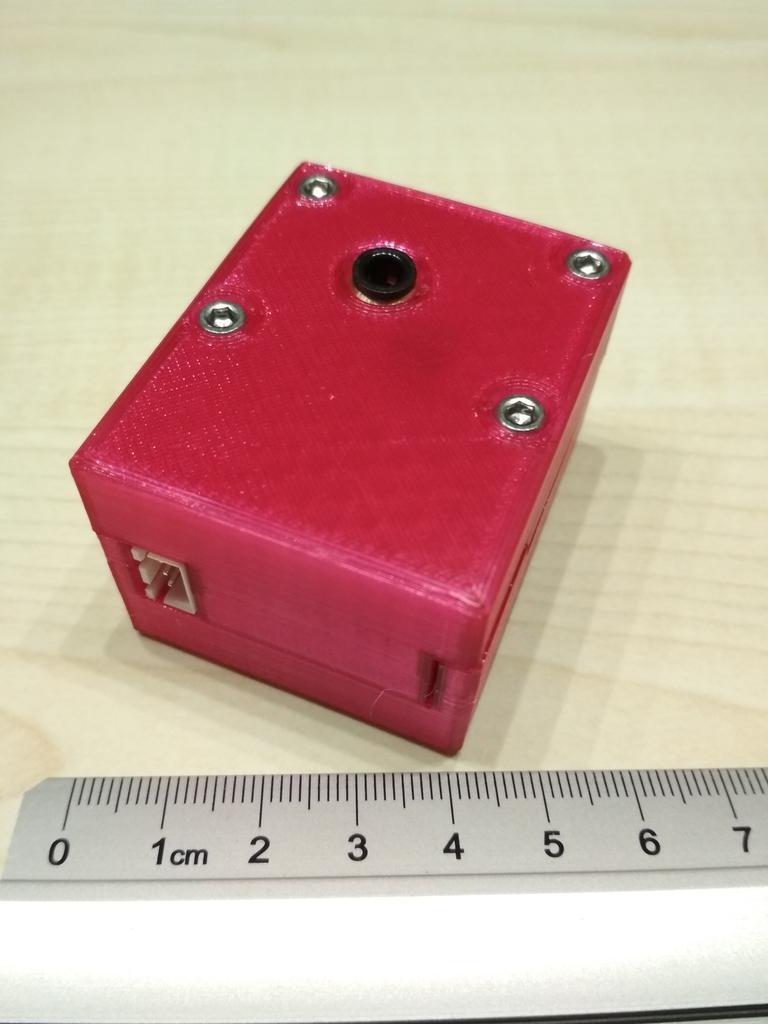

Closed Loop Filament Sensor

thingiverse

This is my version of a filament sensor designed specifically for 1.75mm filament. If it's supported by the printer's software, it can be used to build a closed-loop monitoring system. This means the printer calculates the amount of filament that should be used and receives feedback on how much has actually been used. This way, the sensor can detect not only simple out-of-filament conditions but also various types of filament jams or clogged nozzles. Be aware that this is still a work in progress! So far, I've tested it only on my desk, not in the printer. Next, I need to figure out how to modify Marlin for this purpose. I will update this description as soon as it has been thoroughly tested in the printer. If you'd like to give it a try, you'll need these parts: - 1x optical endstop: https://www.aliexpress.com/item/Free-Shipping-Optical-Endstop-Light-Control-Limit-Optical-Switch-for-3D-Printers-RAMPS-1-4/32246136817.html - 3x 686ZZ ball bearings. - 1x small Lego Tire 14 x 6 mm, Part Color Code: 4246901, Item No: 50945. You can get it from Lego, ebay or Bricklink: https://www.bricklink.com/v2/catalog/catalogitem.page?P=50945 - 2x E3D Embedded Bowden Couplings: https://e3d-online.com/embedded-bowden-couplings-for-metal-1-75mm-filament - 2x screw M3x10, DIN912, with nuts - 4x screw M3x30, DIN912, with nuts - One drop of cyanoacrylate glue (CA) Some hints for printing the parts: It's crucial that you print the encoder wheel from solid black material to ensure a clean optical and electrical signal. You should also make sure there are no visible gaps in it. You can control this by adjusting your printing speed or parameters like 'Outline Overlap' (S3D) in your slicer. I had to set 'Outline Overlap' to 25% for best results. I recommend printing the housing from clear or transparent material so that the lighting of the endstops LED is visible. I've printed everything with PETG, and the small parts have 100% infill while the housing parts have 35% infill (Honeycomb). If you don't intend to use the sensor within a closed chamber 3D printer, PLA should work as well. Every part can be printed without any support. Both pieces of the encoder wheel are designed to be glued together with some CA and a short piece (max. 10mm) of 1.75mm filament for aligning them. The Bowden Couplings can be inserted by carefully using a solder iron, preferably one that's temperature-controlled with a temperature set not too high (200°C works for me).

With this file you will be able to print Closed Loop Filament Sensor with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Closed Loop Filament Sensor.