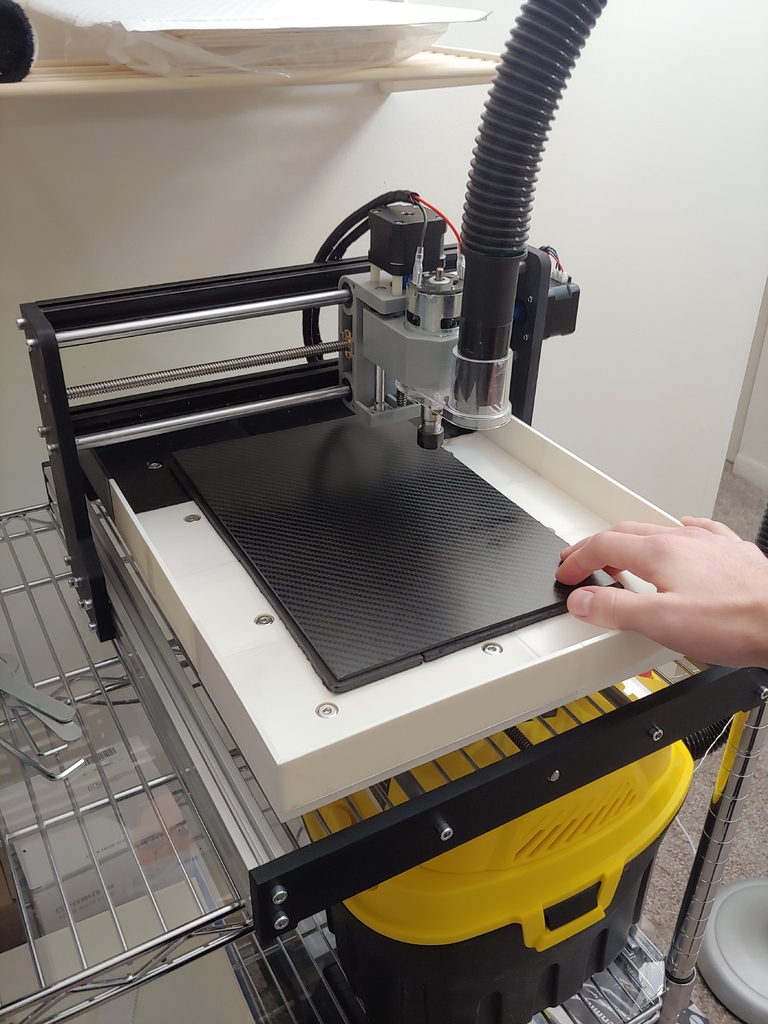

CNC 3040 Water Bath for Milling Carbon Fiber

thingiverse

### CNC 3018 Water Bath To cut carbon fiber, it is important to take the necessary safety precautions: upon cutting, small dust particles are released into the air, and **inhaling it may cause lung cancer**. The particulate released is quite small, and thus air filtration via vacuum is not a reliable deterrent. Enter water bath: by cutting carbon fiber under water, all dust particles are trapped in the water, thus making indoor cutting feasible. This water bath is designed for use with the CNC 3018 milling machine, and can accommodate work pieces up to 40 cm X 30 cm X 1 cm in dimension. Note that this water bath is for the CNC 3040, which is a CNC 3018 with an extended bed. If you are looking for a water bath for the smaller CNC 3018, please see this link: https://www.thingiverse.com/thing:5903699 #### Required Materials * 1 kg ABS filament; quantity: 1 * Water vacuum; quantity: 1; link: https://www.amazon.com/gp/product/B07QG3X6KQ/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 * 3030 Series M6 T-Nut; quantity: 12; link: https://www.amazon.com/gp/product/B07PGN3S3V/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 * M6-1.0 x 16mm Flat Head Hex Socket Cap Screws; quantity: 12; link: https://www.amazon.com/gp/product/B08JC2WMC3/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 * Nitrile Rubber O-Rings 10mm OD 6mm ID 2mm Width; quantity: 12; link: https://www.amazon.com/gp/product/B07F36K44K/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 * small paintbrush; quantity: 1; local hardware store * 1 Liter acetone; quantity: 1; local hardware store #### Build Process 1. Print two A pieces, two B pieces, and two C pieces 2. Tack them together with superglue 3. Pour a small amount of acetone into a glass container 4. Take a paintbrush and seal the crevices with the acetone: this makes it water tight 5. Print out the 'T-nut Positioning Tool' (see section below) and use it to position the twelve T-nuts in the aluminum milling surface 6. Secure the water bed to the milling surface with the twelve bolts: be sure to put the O-rings onto the bolts before threading them with the T-nuts! Check that the bolts are sufficiently tightened such that the O-rings are compressed and provide a watertight seal #### Cutting Process 1. Secure a spoil board (e.g. foam board) to the water bed surface using double sided table (e.g. carpet tape). 2. Secure the carbon fiber to the spoil board using double sided tape 3. Fill the water bed with water such that the work piece is submerged 4. Cut the carbon fiber 5. Suck out the polluted water with the water vacuum 6. Dispose the polluted water

With this file you will be able to print CNC 3040 Water Bath for Milling Carbon Fiber with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on CNC 3040 Water Bath for Milling Carbon Fiber.