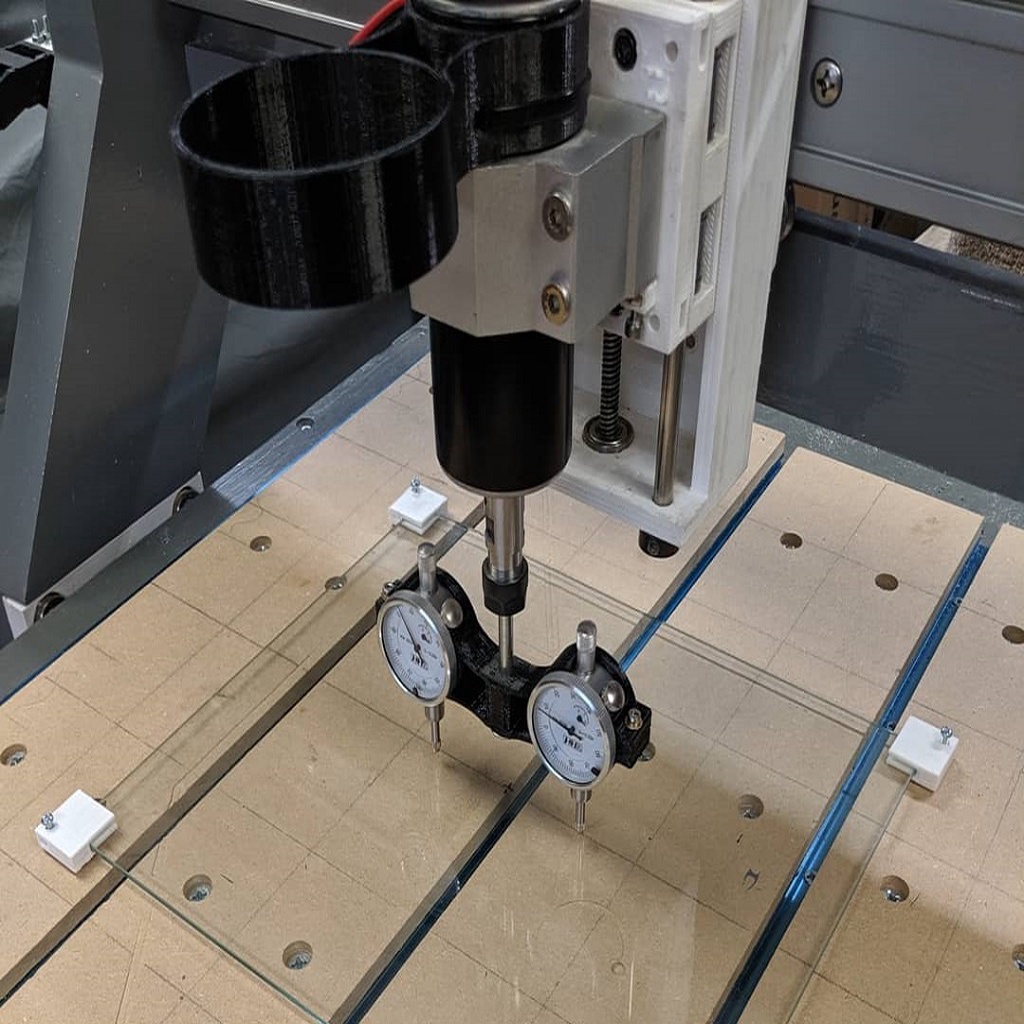

CNC Tramming Plate Adjuster

thingiverse

You can use a glass plate to help tram your CNC per various YouTube videos out there, but instead of playing cards or stacked materials at the corners, design this to be placed at each corner to level the glass plate prior to tramming. The adjuster is designed to fit a 3mm glass plate and house 3mm nuts within its cavity at the outside edge with a 3mm screw threaded down through it. The premise involves installing one of these at each corner, threading each screw about 1 mm out through the bottom, then setting the plate on the CNC bed. Run an indicator inserted into your spindle's collet to one corner where you set the indicators zero, then run to each other three corners and adjust the screw up or down until each is at zero. When all four corners are zero on the indicator, the plate is level and you can begin tramming your spindle in relation to the plate. The bed is then surfaced. This helps save time, making it easier to tram your spindle every so often without messing around with shims or playing cards. I've oriented the model for easy cleanup (the little square hole for the nut is a pain if printed horizontally) but you can orient it however best suits your needs.

With this file you will be able to print CNC Tramming Plate Adjuster with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on CNC Tramming Plate Adjuster.