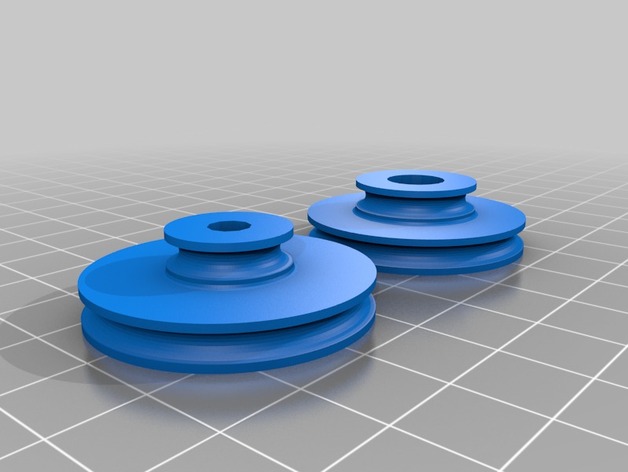

Compound pulley and bearing plate for slowing a drill press

thingiverse

I made these pulleys in an attempt to use a standard 12k/8k wood drill press for drilling stainless steel. I had previously been controlling the pressure by hand to partially stall the motor and slow it down to the requisite speed for drilling steel, but wore down a number of HSS-Co drill bits in the process. The original drill press had two compound pulleys: driving pulley attached to the motor: 17mm and 22mm output pulley attached to the drill head: 22mm and 33mm This thing adds a bearing plate holding two standard 625 bearings (5x16x5) and compound pulleys that can be attached using M5 cap screws. Sources are here: https://github.com/hyperair/drill-press-pulleys Instructions Push the 625 bearings into the bearing plate. Thread an M5 screw through each pulley and bearing, with an M5 washer in between. Seal with an M5 nylock nut on the top. Figure out how to route the belts correctly. Small to big, basically, going from the driving pulley to the output pulley. Don't assemble it in reverse unless you're sure the drill is going to be happy with it -- it totals up to about a 8x speed difference, so 12k RPM x 8 = 96k RPM. I'm not sure what will blow at that point. Replace drill press safety cover before turning on in case the whole assembly explodes.

With this file you will be able to print Compound pulley and bearing plate for slowing a drill press with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Compound pulley and bearing plate for slowing a drill press.