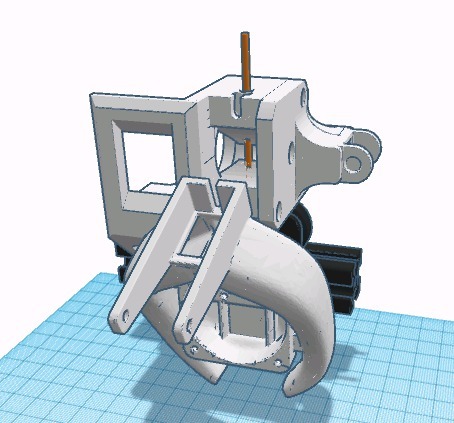

CR-10 Direct Drive extruder with integrated RSE-2

thingiverse

Got another one. This time I took the beefed up direct mount and added the RSE-2 extruder onto it as a single unit. Lined everything up with Ross_K's carriage model and my own crappy representation of my MircroSwiss heatsink. The Noclearance file is for you to add your own cutouts to clear whatever cooling solution you have. The fang file is already pre-clearanced for 2bedom's MicroSwiss fang. Edit: Added FilamentSaver file. This one is to test attachment to the carriage, position of the outlet tube to line up with the heatsink Bowden, and sizing of the hole to receive the Bowden. Planning on printing out a low infil PLA test part this morning to see if there are any problems before going all in with PETG. Update 2/26: Printed out the FilamentSaver in Hatchbox white PETG. Seems to fit perfect except the hole for the bowden tube is too small. I'm measuring about 3.5mm when it was supposed to be 4.2mm. Don't know why it shrunk so much more than everything else but I'll play with it. Uploaded three MKII files, these have the bowden hole enlarged to 5.2mm from 4.2mm, a 120% increase to match the shrinkage encountered. I know it will probably bite me since the full versions are printed at a different orientation than what I printed the test. Update 2/28: Added MKIII Fangclear file, fixed a small clearance issue with the left guide wheel. Also enlarged the hole for the bolt which holds this wheel on, was a little tight on my Filamentsaver model that I printed. Also added a cover for the RSE2 extruder with a drag chain attachment molded in. Hopefully it should line up well enough and not get in the way. Used stevenfayers Z chain links, I don't have a fixed end modeled yet. The hole in the direct drive mount is for a 20x20 heatsink on the stepper, by the way, I forgot to mention that. Added MKIII-BowdenIn file. Should be able to thread a 5mm pushlok into it, made hole 4.78mm. Update 2/28: Printed out the MKIII Bowden version. I was right, enlarged the hole too much. 5.2mm in CAD came out 4.8mm on print. Still going to install it and make sure there's no other problems. Looks good just looking at it. Got some stringing and ugly places. Used Hatchbox white PETG.

With this file you will be able to print CR-10 Direct Drive extruder with integrated RSE-2 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on CR-10 Direct Drive extruder with integrated RSE-2.